Mastering Chicago Couplings: The Ultimate Guide for Industry Professionals

Welcome to the definitive guide on Chicago couplings, an indispensable component across various industries. This article is designed to provide a comprehensive understanding of Chicago couplings, from their basic mechanics to installation and maintenance best practices. Whether you’re a seasoned professional or new to the field, this guide offers valuable insights and practical tips to enhance efficiency and safety in your operations.

1: Understanding Chicago Couplings

Definition and Mechanics

Chicago couplings, or universal couplings, are quick connect-disconnect fittings used primarily for air, water, and pneumatic applications. They consist of a male end, a female end, and a locking head for secure attachment, facilitating easy and efficient hose connections without the need for tools.

Historical Background

Originating in the bustling industrial scene of Chicago, these couplings were named after the city where they were widely popularized. Their design was born out of necessity for quick, reliable connections in a variety of industrial applications, streamlining operations and enhancing safety.

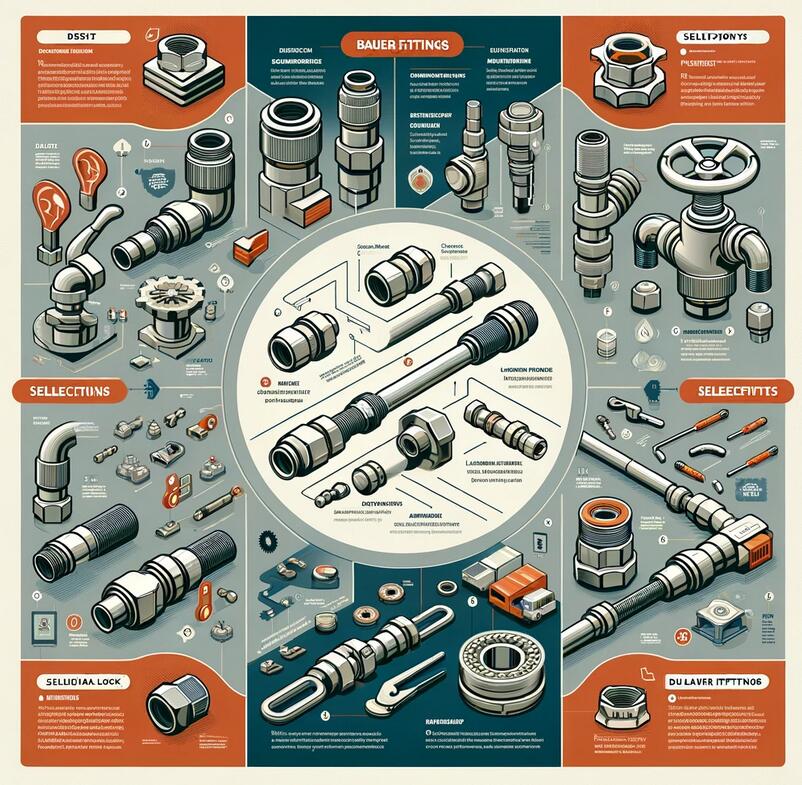

Types and Applications

- Standard Hose Ends: Commonly used for air and water services in construction and manufacturing.

- Twist-Lock Ends: Offer a secure connection for high-pressure applications, ideal for mining and industrial cleaning.

- Universal Ends: Compatible with multiple sizes and types of hoses, providing flexibility across different tasks.

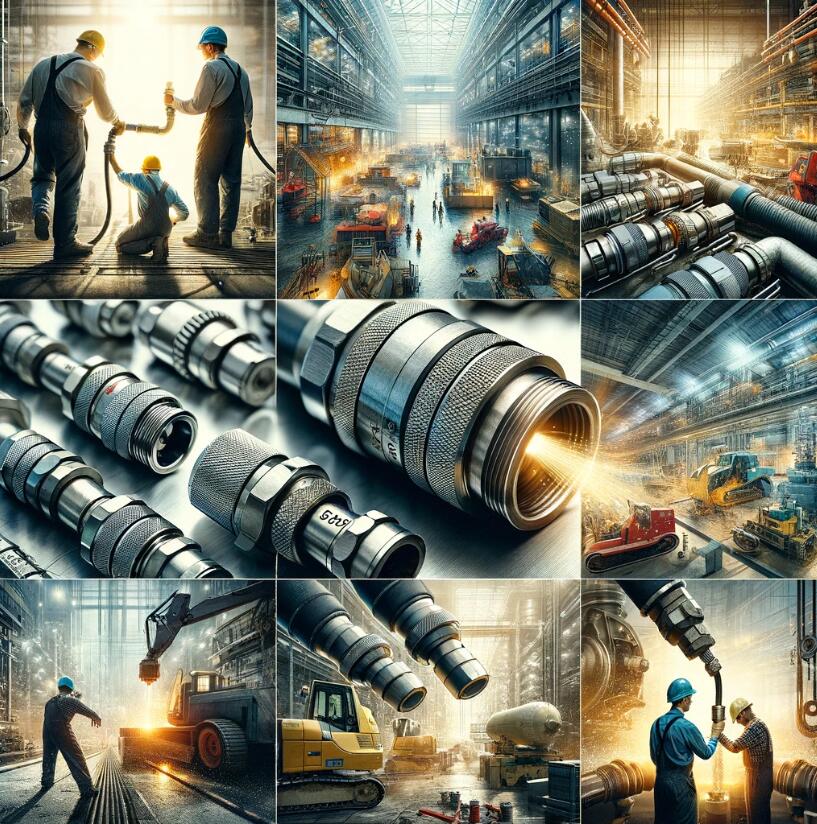

2: The Significance of Chicago Couplings in Industry

Case Studies

Demonstrating their versatility, Chicago couplings have improved operational efficiency and safety. For example, in the construction industry, quick-connect couplings have reduced equipment setup times, allowing for faster project completions. In manufacturing, they minimize downtime by enabling rapid tool changes and maintenance.

3: Choosing the Right Chicago Coupling for Your Needs

Factors to Consider

- Material Compatibility: Ensuring the coupling material is suitable for the fluid being transported.

- Size and Pressure Rating: Matching the coupling size and pressure capabilities with the hose and application requirements.

- Connection Type: Selecting the appropriate end fitting based on the equipment and hose compatibility.

Brand and Model Comparison

With numerous brands and models on the market, conducting a thorough comparison is important. Factors such as durability, ease of use, and customer support can influence decision-making. Brands like Dixon, Eaton, and Parker are renowned for their quality and range of options.

4: Installation and Maintenance Best Practices

Installation Guide

Proper installation is crucial for the performance and longevity of Chicago couplings. Steps include inspecting the coupling and hose for damage, securely attaching the coupling to the hose, and testing the connection under controlled conditions to ensure it’s leak-free.

Maintenance Tips

- Regular Inspection: Routine checks for wear, damage, and leaks can prevent failures.

- Cleaning: Keeping couplings clean from dirt and debris extends their life and maintains a good seal.

- Lubrication: Applying appropriate lubricants to moving parts can reduce friction and wear.

Chicago couplings play a critical role in various industrial applications, offering ease of use, reliability, and safety. Understanding the types, applications, and best practices for selection, installation, and maintenance is essential for maximizing their benefits. Professionals can ensure efficient and safe operations of their Chicago couplings by following the guidelines in this guide, contributing to optimal performance and longevity.

Embrace the potential of Chicago couplings in your industry by staying informed, selecting the right components, and adhering to best practices for installation and maintenance. The versatility and reliability of Chicago couplings make them an invaluable asset for any operation.

5: Safety Considerations and Compliance

Safety Protocols When Using Chicago Couplings

Safety is paramount when using Chicago couplings, especially in high-pressure applications. Proper handling and usage are crucial to prevent accidents and ensure the well-being of personnel. Key safety protocols include:

- Training employees on correct coupling selection, installation, and maintenance procedures.

- Wearing appropriate personal protective equipment (PPE) during installation and maintenance.

- Conducting regular inspections to detect wear and tear, replacing defective parts immediately.

Compliance with Industry Standards and Regulations

Chicago couplings must comply with relevant industry standards and regulations, meeting safety, quality, and performance criteria. Standards such as ISO 7241 (for hydraulic and pneumatic couplings) and the Occupational Safety and Health Administration (OSHA) guidelines in the United States provide frameworks for compliance. Adherence to these standards ensures operational safety and enhances the couplings’ reliability and longevity.

Regular Safety Inspections and Certifications

Regular safety inspections and certifications are essential to verify that Chicago couplings are in optimal condition and compliant with safety standards. Inspections should cover the coupling’s physical condition, connection integrity, and operational performance. Certification from recognized authorities can also serve as proof of compliance, contributing to higher safety and reliability standards in industrial applications.

6: Innovations and Future Trends in Chicago Couplings

6: Innovations and Future Trends in Chicago Couplings

Emerging Technologies in Design and Manufacturing

The design and manufacturing of Chicago couplings are witnessing significant advancements, incorporating new materials and technologies to meet evolving industry needs. Innovations such as smart couplings equipped with sensors for real-time monitoring of pressure and flow rates are becoming more prevalent. These technologies enhance safety and efficiency by providing early warnings of potential issues, enabling proactive maintenance to prevent failures.

Sustainability and Eco-friendly Materials

As industries move towards more sustainable practices, the development of Chicago couplings is also evolving. Manufacturers are exploring using eco-friendly materials and manufacturing processes to reduce environmental impact. This includes recyclable materials and designs that minimize waste and energy consumption during production, aligning with global sustainability goals.

Future Developments

The future of Chicago couplings looks promising, with ongoing research and development to enhance their performance, reliability, and environmental sustainability. Material science and engineering advances will likely lead to lighter, stronger, and more durable couplings. Furthermore, integrating digital technologies, such as the Internet of Things (IoT), will enable smarter, more connected systems, facilitating predictive maintenance and improving operational efficiency.

Conclusion

Chicago couplings represent a critical component in the machinery of various industries, offering unmatched versatility and efficiency. By understanding their types, applications, and best practices for selection, installation, and maintenance, professionals can leverage these couplings to enhance operational efficiency and safety. Looking ahead, the future of Chicago couplings will be shaped by design, technology, and sustainability innovations, ensuring they remain a vital tool in the industrial landscape.

Embracing the advancements in Chicago couplings contributes to more efficient and safe operations and aligns with the broader goals of sustainability and innovation. As the industry evolves, staying informed and adaptable to these changes will be key to maximizing the potential of Chicago couplings in any industrial application.