The Ultimate Guide to Inox Press Fittings: Features and Benefits

Whether you’re an industry professional or simply interested in modern construction trends, the realm of inox press fittings offers intriguing advancements. This guide will unravel the features and benefits of these cutting-edge fittings, painting a clear picture of why they’re quickly becoming a top choice.

Understanding Inox Press Fittings

History and Evolution of Press Fittings

The world of plumbing and construction has witnessed a series of innovations, with press fittings being a major milestone. Traditionally, fittings were cumbersome, often requiring soldering or welding. Enter press fittings: a revolutionary leap that streamlined the installation process. When coupled with inox, which refers to stainless steel, these fittings improve durability and resilience.

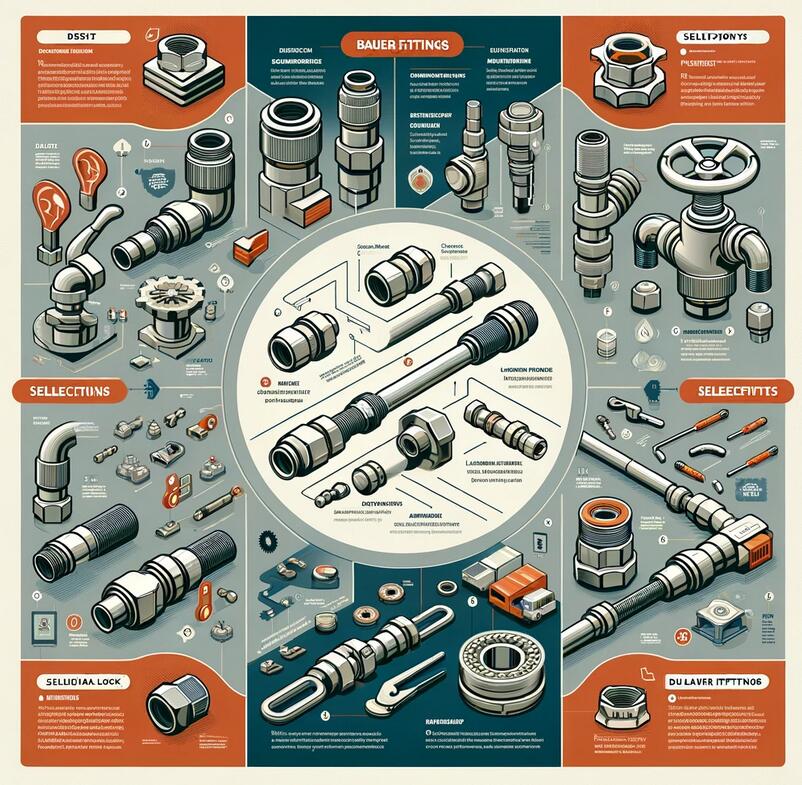

Basic Components and Varieties

At its core, an inox press fitting is an engineering marvel. It typically has a stainless steel body, a pressing profile, and a durable seal. Today’s market provides numerous choices:

- Elbows: For directing flow.

- Couplings: To connect pipes seamlessly.

- Reducers: Essential for adjusting pipe size.

- Tees: For pipe branching without leaks.

The variety ensures that there is an inox press fitting solution for almost every need.

Key Features of Inox Press Fittings

Durability and Strength

The inherent qualities of stainless steel, such as resistance to corrosion, give inox press fittings an edge. These fittings resist environmental threats, ensuring longevity. The science is clear: When chromium is present in stainless steel, When it comes into contact with oxygen, it produces a protective layer that stops rust and decay from occurring.

Ease of Installation

Gone are the days when fittings installation meant hours of labor. With inox press fittings:

- No soldering or welding is required.

- Simple tools make the process seamless.

- Installation errors are significantly reduced.

For contractors, this saves time and reduces labor costs.

Safety and Leak Prevention

Safety is paramount in plumbing. Inox press fittings shine in this arena due to their robust design. The seals ensure a watertight connection, preventing leaks, which can lead to structural damage or mold growth. Properly installed fittings stand the test of time, minimizing the need for frequent check-ups or overhauls.

Versatility in Applications

The adaptability of inox press fittings is remarkable. These fittings prove invaluable, be it a residential home, a skyscraper, or an industrial plant. Compatibility with various pipe materials means they can be easily integrated into diverse systems.

Benefits of Adopting Inox Press Fittings

Cost-Effectiveness Over Time

While the initial investment in inox press fittings might be higher compared to traditional fittings, the long-term benefits are compelling:

- Reduced maintenance costs due to fewer leaks.

- Savings on labor due to faster installation.

- Longevity means less frequent replacements.

The cost benefits become undeniable When viewed over a project’s lifespan.

Environmental and Health Advantages

Stainless steel is a green material. Its ability to be recycled, coupled with its long lifespan, makes inox press fittings an eco-friendly choice. Additionally, reduced leaks mean lesser water wastage and prevention of mold growth, fostering a healthier living environment.

Space-Saving Designs

In modern construction, where space is at a premium, inox press fittings offer compact designs. This is crucial for projects with spatial constraints, allowing for more efficient usage of available space.

Enhanced Flow Efficiency

The streamlined design of inox press fittings ensures an unhindered flow. This is especially beneficial in systems that demand efficient flow rates, such as central heating or industrial processes.

Best Practices for Using Inox Press Fittings

Selecting the Right Type of Fitting

Choosing the appropriate fitting is pivotal. Consider the project needs, whether residential or industrial and match the fitting specifications accordingly. For instance, an industrial setup might prioritize flow rate, dictating a specific type of fitting.

Installation Tips and Tricks

For optimal results:

- Ensure the pipes are cut squarely.

- Deburr the pipe ends to prevent seal damage.

- Mark insertion depth to ensure a full insertion.

- Always pressure test the system before full usage.

While inox press fittings simplify installation, diligence is essential to maximize their benefits.

Conclusion

The world of inox press fittings offers innovations transforming modern plumbing and construction. Their durability, ease of installation, versatility, and cost-effectiveness make them a top choice for professionals and homeowners. One can leverage their full potential by understanding their features and benefits, ensuring efficient, safe, and long-lasting systems.

Case Studies

Residential Complex with Inox Press Fittings

In a recent upscale residential development in Miami, inox press fittings were the choice for the entire plumbing system. The project faced challenges, including tight deadlines and the humid coastal environment notorious for accelerating corrosion in metallic components.

The decision to opt for inox press fittings resulted in:

- A 30% reduction in installation time compared to traditional fittings.

- No reported leaks or fitting-related issues post-completion.

- An aesthetically pleasing finish complements the complex’s modern design.

Feedback from residents has been overwhelmingly positive, with many praising the efficiency and reliability of the plumbing system. This case underscores the benefits of inox press fittings in residential scenarios, especially when faced with environmental challenges.

Industrial Application of Inox Press Fittings

A renowned beverage production plant in Germany underwent a major overhaul of its liquid processing unit. Given the scale, downtime had to be minimized, and the integrity of the plumbing system was paramount to ensure product quality.

The adoption of inox press fittings led to:

- Streamlined installation, reducing downtime by 40%.

- Enhanced flow efficiency, optimizing production rate.

- A robust system resilient to the acidic by-products of beverage processing.

The long-term performance analysis highlighted the negligible maintenance requirements and the fittings’ enduring quality even under rigorous use. This case illustrates the efficacy of inox press fittings in demanding industrial settings.

Conclusion

As we navigate the intricacies of inox press fittings, their transformative potential in construction and plumbing becomes evident. From upscale residential complexes braving coastal challenges to industrial plants aiming for optimized production, the applications are diverse and compelling.

The move from traditional systems, often laden with prolonged installation timelines and potential vulnerabilities, to the quick, efficient, and durable inox press fittings signifies a leap towards better, more sustainable construction practices.

The myriad features – unparalleled durability, cost-effectiveness, environmental benefits, and unmatched versatility – position inox press fittings as the gold standard in modern-day plumbing solutions. For architects, builders, contractors, and homeowners, the message is clear: Inox press fittings are not just a trend but a testament to where the future of plumbing is headed.

References and Further Reading

For those keen on delving deeper, the following resources provide extensive insights into inox press fittings:

- Smith, J. (2019). *Modern Plumbing: The Rise of Press Fittings*. New York: Construction Chronicles.

- International Plumbing Association. (2021). *Annual Review: Innovations in Plumbing*.

- Turner, L., & Williams, R. (2020). *Stainless Steel in Construction: Durability and Aesthetics*. London: Building Tomorrow.

Appendix

Glossary of terms related to inox press fittings:

- Press Fitting: A connection method using a pressing tool to crimp a fitting onto a pipe, creating a watertight seal.

- Inox: Derived from French “inoxydable”, referring to stainless steel.

- Reducer: A fitting used to connect pipes of different sizes.

FAQs about inox press fittings:

Q: How long do inox press fittings last?

A: With proper installation and under normal conditions, inox press fittings can last several decades, thanks to the durability of stainless steel.

Q: Can inox press fittings be used outdoors?

A: Yes. Due to their corrosion-resistant nature, inox press fittings are suitable for outdoor applications, even in challenging environments.

Q: Are special tools required for their installation?

A: While standard plumbing tools can be used for many tasks, a pressing tool is essential to ensure a secure connection when installing inox press fittings.

The realm of inox press fittings is vast, innovative, and forward-looking. These fittings are a favorite as we embrace modern construction methods and prioritize efficiency and sustainability. This guide has endeavored to shed light on their myriad benefits, hoping to inform and inspire better building choices for the future.