A Guide to Choosing the Right Type of Stainless Steel Pipe Fitting for Your Project

Are you looking for stainless steel pipe fittings that are reliable and long-lasting? BR INDUSTRY is the world’s leading manufacturer and exporter of top quality stainless steel pipe fitting. In this article, we will explore the different types of pipe fittings available as well as tips on how to select the right type for your project. We will also discuss advantages and disadvantages of each type, installation instructions, maintenance advice and much more!

Introduce stainless steel pipe fittings

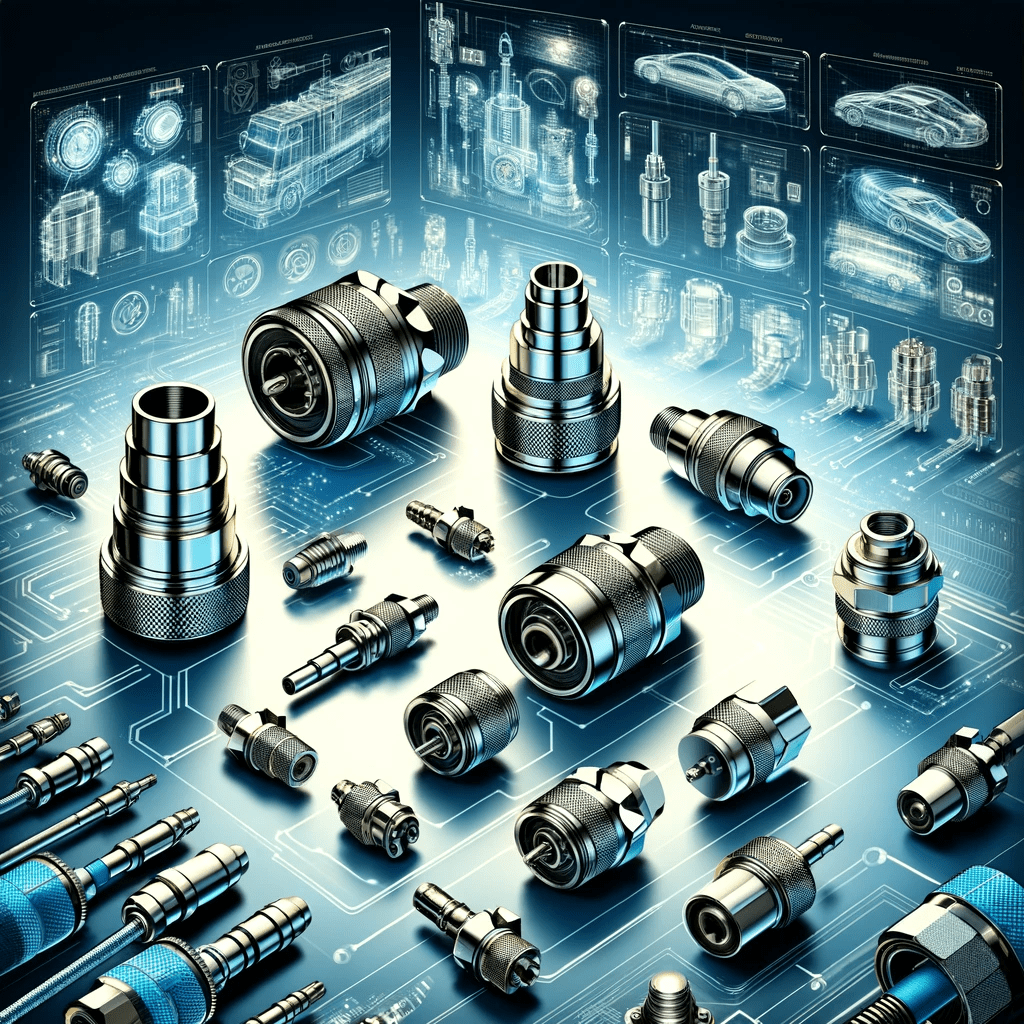

We have an extensive selection of products that are designed to provide reliable performance in any application. Our stainless steel pipe fittings come in a variety of styles, sizes, and grades including 304, 316L, 321/H, 347/H, 410S and more. With our vast range of options we can supply you with the perfect fitting for your project needs. All our fittings are manufactured using high-grade materials that ensure superior strength and durability even under extreme conditions. All our products meet or exceed industry standards so you can be sure they offer the highest level of quality possible.

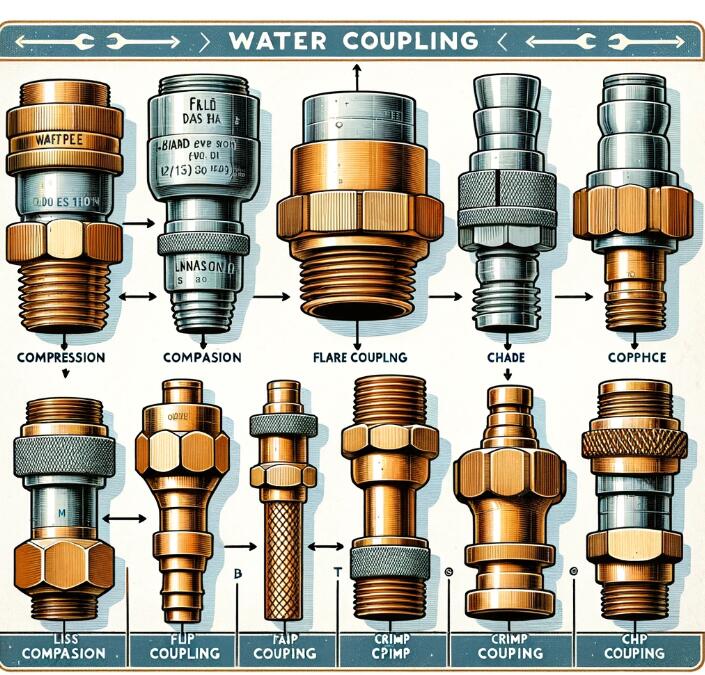

Explain the different types of stainless steel pipe fittings available

BR INDUSTRY offers a wide range of fittings that are perfect for any project. Our offerings include threaded fittings, butt weld fittings, socket weld fittings, and flanges in various sizes and grades. We also offer specialty items such as reducers, tees and elbows to meet the needs of more complex projects. Each type has its own advantages and disadvantages so it is important to consider your individual requirements when deciding which option is best suited for your application. Threaded fittings provide easy installation while butt welds offer superior strength but require professional welding expertise during installation. Socket welds deliver reliable performance with minimal maintenance while flanges create secure seals but may require additional support or reinforcement due to their larger size.

Discuss the advantages and disadvantages of each type of fitting

When it comes to choosing the right type of stainless steel pipe fitting for your project, there are a variety of options available. Each type has its own advantages and disadvantages so it is important to consider your individual requirements when deciding which option is best suited for your application. Threaded fittings provide easy installation while butt welds offer superior strength but require professional welding expertise during installation. Socket welds deliver reliable performance with minimal maintenance while flanges create secure seals but may require additional support or reinforcement due to their larger size. In this article, we will discuss the different types of fittings available as well as tips on how to select the right type for your project. We will also explore the advantages and disadvantages of each type, installation instructions, maintenance advice and much more!

Outline how to select the right type for your project based on factors such as cost, durability, ease of installation, etc.

Selecting the right type of pipe fittings for your project is essential to ensure that your installation meets all safety and performance requirements. When selecting a fitting, it is important to consider factors such as cost, durability, ease of installation and maintenance. For example, threaded fittings are typically less expensive than other types but may require more frequent replacement due to their relatively low strength. On the other hand, butt welds offer superior strength but require professional welding expertise during installation which can add additional costs. Socket welds deliver reliable performance with minimal maintenance while flanges create secure seals but may require additional support or reinforcement due to their larger size. Carefully considering these factors will help you choose the best option for your particular project needs.

Provide tips on how to install and maintain stainless steel pipe fittings correctly

Installing and maintaining fittings correctly is essential for ensuring that your project meets all safety and performance requirements. With the right preparation, knowledge, and tools you can be sure that your installation will last for years to come. Here are some tips on how to install and maintain pipe fittings correctly so you can get the most out of them.

Stainless steel pipe fittings offer a variety of advantages and disadvantages depending on the type you choose. It is important to consider your individual requirements when deciding which option best suits your project needs. Threaded fittings provide easy installation, butt welds offer superior strength but require professional welding expertise during installation, socket welds deliver reliable performance with minimal maintenance while flanges create secure seals but may require additional support or reinforcement due to their larger size. With the right preparation, knowledge, and tools you can ensure that your pipe fitting installations are done correctly for years of lasting performance.