Exploring Efficient Alternatives to Camlock Connectors: A Comprehensive Guide

Introduction

Welcome to our comprehensive guide on exploring efficient alternatives to camlock connectors. This article provides insights into connector technology, covering alternatives to traditional camlock connectors. Used widely across different industries, understanding these connectors and their alternatives is crucial for anyone looking to optimize their operations.

Understanding Camlock Connectors

Camlock connectors, also known as cam and groove couplings, are a popular type of hose coupling used in various industrial applications. These connectors are known for their ease of use, as they allow for quick connection and disconnect without additional tools. Camlock connectors are used in medium to high-pressure applications and are typically made from materials such as stainless steel, aluminum, and polypropylene.

Design and Functionality

The design of a camlock connector consists of a male (plug) and female (socket) end, which lock together with a simple lever operation. This simplicity in design ensures a secure connection that can withstand various pressures and temperatures, depending on the material used.

Applications in Various Industries

Camlock connectors find use across multiple industries, such as oil and gas, pharmaceuticals, agriculture, and chemical processing. Their applications range from transferring liquids and powders to providing secure connections in fluid control systems.

Advantages and Limitations of Camlock Connectors

While camlock connectors are favored for their quick and easy operation, they also come with certain limitations. Their suitability can vary depending on the environment, temperature, and the type of material being transferred. Moreover, there may be better choices than camlock connectors in certain high-pressure or corrosive environments.

Why Look for Alternatives?

The search for alternative camlock connectors usually stems from the need to overcome these limitations. Whether it’s a requirement for higher pressure tolerances, better chemical resistance, or more durable materials, exploring alternatives can offer solutions better tailored to specific industrial needs.

Challenges in Specific Environments

In environments where extreme temperatures or corrosive substances are involved, alternatives to camlock connectors can provide enhanced performance and safety. For instance, in high-pressure applications, a more robust connector might be necessary to prevent leaks and ensure worker safety.

Evolution of Industry Needs

As industries evolve and new challenges emerge, the demand for more advanced connector solutions grows. This evolution drives the development of alternatives to meet these emerging requirements more effectively.

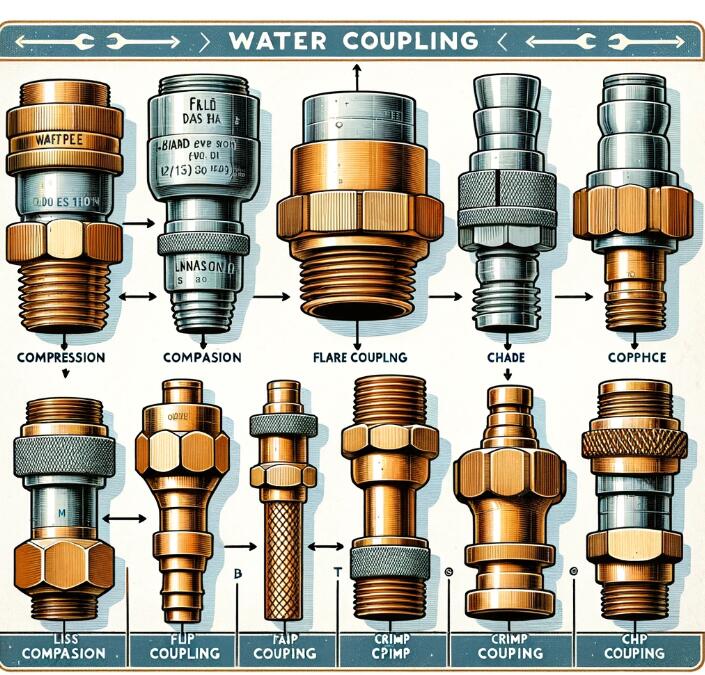

Top Alternatives to Camlock Connectors

Several alternatives to camlock connectors have gained popularity due to their specialized features. These include dry disconnect couplings, quick-release couplings, and threaded connectors, each offering unique advantages in certain scenarios.

Detailed Comparison

Each of these alternatives brings something different to the table. Dry disconnect couplings, for example, are designed to minimize spillage during disconnection, making them ideal for transferring hazardous materials. On the other hand, quick-release couplings offer an even faster connect and disconnect feature than cam locks, which is useful in emergencies.

Technical Comparison: Camlock Connectors vs. Alternatives

To understand the best fit for a specific application, a technical comparison is essential. This involves evaluating pressure ratings, material compatibility, and ease of use. A connector that excels in high-pressure environments may not necessarily be the best choice for chemical resistance, and vice versa.

Performance Metrics

Evaluating connectors based on durability, ease of use, and safety features is crucial. For example, in the food and beverage industry, connectors must be durable and comply with strict hygiene standards.

Environmental Considerations

Environmental factors such as temperature, exposure to chemicals, and the physical demands of the operating environment are critical in choosing the right connector. Each alternative offers different benefits in these areas, influencing the decision-making process.

In conclusion, while camlock connectors are a reliable and widely used solution in many industries, exploring alternatives is essential for specialized applications. Understanding these alternatives, their advantages and limitations, and how they compare technically to camlock connectors can lead to more informed and efficient choices in connector technology.

Cost and Availability Analysis

Cost and availability play significant roles When considering alternatives to camlock connectors. The cost of these alternatives can vary based on the materials and design complexity. For instance, stainless steel connectors are generally more expensive than aluminum or plastic but offer better durability and corrosion resistance.

Cost Comparison

Comparing the costs of different types of connectors is not just about the initial purchase price. It’s also important to consider the long-term costs associated with maintenance, durability, and potential downtime caused by connector failures. In some cases, investing in a more expensive connector can result in long-term cost savings because it has a longer lifespan and is more reliable.

Availability and Sourcing Options

The availability of connector alternatives can vary depending on the region and specific industry needs. Some connectors are readily available in large industrial markets, while others may need to be sourced or custom-made for specific applications. This can affect both the lead time and the cost.

Installation and Maintenance Insights

Proper installation and regular maintenance are crucial for ensuring any connector’s longevity and optimal performance, whether it’s a traditional camlock or an alternative. Each connector type comes with its own installation guidelines and maintenance requirements.

Guidance on Installing Various Connector Types

Installation procedures can vary significantly between different types of connectors. For instance, while camlock connectors are relatively straightforward to install, dry disconnect couplings require more careful alignment and handling. Providing clear installation instructions and training for staff is essential in preventing leaks and ensuring safety.

Tips for Maintenance and Longevity

Regular maintenance, such as inspecting for wear and tear, cleaning, and replacing worn parts, can greatly extend the life of connectors. Using the correct tools and following the manufacturer’s guidelines are key factors in maintaining these components effectively.

Troubleshooting Common Issues

Understanding the common issues that can arise with different types of connectors and how to address them is crucial for minimizing downtime. For example, issues like seal wear in quick-release couplings or misalignment in threaded connectors can be swiftly addressed with the right knowledge and tools.

Future Trends in Connector Technology

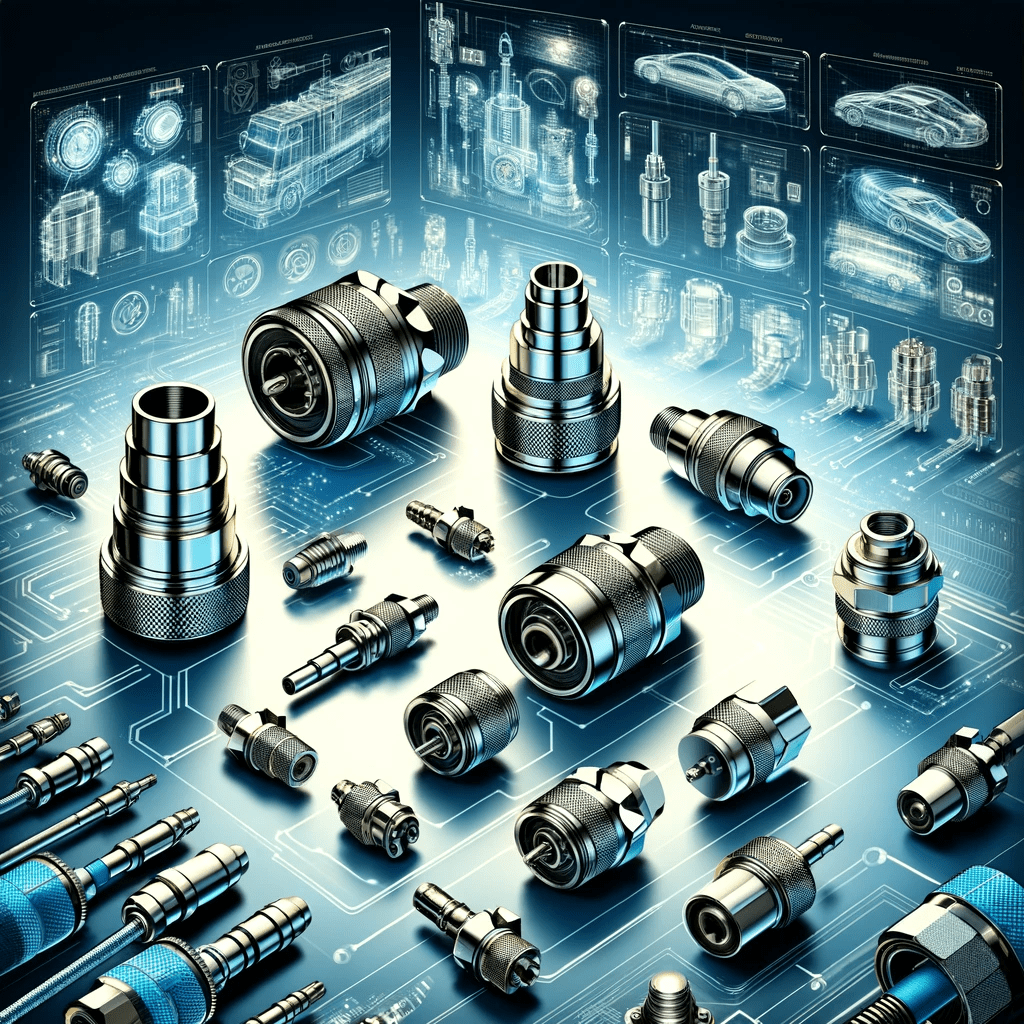

The field of connector technology is rapidly advancing, with innovations emerging regularly. It is vital for industries relying heavily on these components to stay informed about these trends.

Emerging Technologies and Innovations

Recent advancements include the development of smart connectors that can provide real-time data on flow rates and temperatures and connectors made from new composite materials for enhanced strength and chemical resistance. Such innovations can offer significant advantages in various industrial applications.

Predictions about the Future of Connectors

Looking forward, we can expect to see more efficient, robust, and environmentally friendly connectors. The trend towards sustainability is likely to drive the development of connectors made from recyclable materials or designed to minimize environmental impact.

In conclusion, while camlock connectors have been a staple in many industries for years, the evolving demands of these industries necessitate exploring alternative solutions. Businesses can optimize efficiency, safety, and cost-effectiveness by understanding the technical aspects of traditional camlock connectors and alternatives. In the industrial world, staying up-to-date with technological advancements will be crucial to maintain a competitive edge.

With this comprehensive guide, we hope to have provided valuable insights into the world of camlock connectors and their efficient alternatives. Considering all the factors discussed, from technical specifications to future trends, you can ensure that your connector choices align perfectly with your industry’s unique needs and challenges.