Comprehensive Guide on Camlock Fittings Applications

Camlock fittings, or cam and groove couplings, are vital in transferring liquid, gas, and dry products across many industries. Their reliability, ease of use, and efficiency make them a preferred choice for connecting hoses and pipes securely and leak-proof. This article delves deep into camlock fittings, exploring their applications, benefits, types, and selection criteria to understand these indispensable components thoroughly.

Introduction to Camlock Fittings

Camlock fittings are quick-connect, fluid transfer hose couplings used to connect and disconnect hose or pipe without needing tools. They are used in various industries to transport water, chemicals, fuels, and other materials safely and efficiently. The fittings consist of a male “adapter” and a female “coupler” that easily snap together to form a secure connection. Cam arms or levers lock the two parts, ensuring a stable and leak-free connection.

Applications Across Industries

Camlock fittings find applications in numerous industries due to their versatility, durability, and ease of use. Below is a breakdown of their applications across various sectors:

Agriculture

In agriculture, Camlock fittings are used for:

- Irrigation: Connecting hoses and pipes for water distribution.

- Chemical Spraying: Attaching hoses to pesticide and fertilizer application sprayers.

- Livestock Watering: Establishing secure connections for livestock watering systems.

Oil and Gas

The oil and gas industry relies on camlock fittings for:

- Fuel Transfer: Securely transferring fuels from storage tanks to vehicles or equipment.

- Chemical Handling: Connecting hoses to transfer chemicals used in drilling and production.

- Water Disposal: Creating connections for disposing of wastewater generated during drilling.

Pharmaceuticals

Camlock fittings in the pharmaceutical industry are used for:

- Fluid Transfer: Transferring sensitive liquids between processing units while maintaining sanitary conditions.

- Material Handling: Connecting hoses and pipes to transfer raw materials and finished products safely.

Manufacturing

In manufacturing settings, camlock fittings are utilized for:

- Coolant Delivery: Delivering coolants to machinery during manufacturing processes.

- Material Transfer: Securely transferring raw materials and components between different stages of production.

Food and Beverage

Camlock fittings play a crucial role in the food and beverage industry for:

- Beverage Transfer: Transferring liquids such as milk, beer, and juices between tanks and bottling lines.

- Sanitary Applications: Maintaining hygienic conditions while transferring food products.

Benefits of Using Camlock Fittings

The widespread use of camlock fittings can be attributed to their numerous benefits, which include:

- Quick and Easy Connection and Disconnection: Camlock fittings allow for rapid connection and disconnection of hoses and pipes, saving valuable time and effort.

- Leak-Proof: When properly connected, camlock fittings provide a secure, leak-proof connection, ensuring the safe transfer of materials.

- Versatility: They can be used across various industries and with many materials.

- Durability: Camlock fittings, made of stainless steel, aluminum, or brass, have a long service life.

- Cost-Effective: Their durability and efficiency make camlock fittings a cost-effective solution for fluid transfer needs.

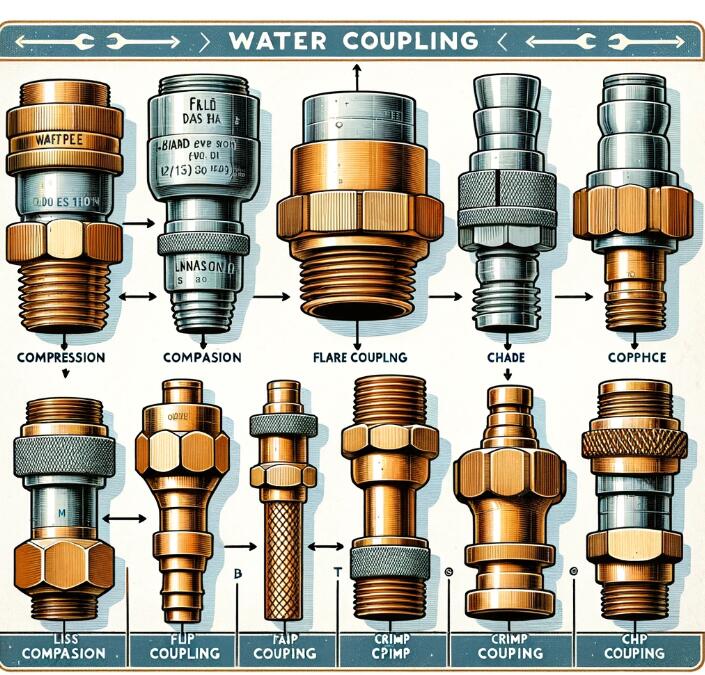

Types of Camlock Fittings

Camlock fittings come in various types, each designed to meet specific needs and applications. The most common types include:

- Type A: Male adapter with a female thread.

- Type B: Female coupler with a male thread.

- Type C: Female coupler with a hose shank.

- Type D: Female coupler with a female thread.

- Type E: Male adapter with a hose shank.

- Type F: Male adapter with a male thread.

- Type DC: Dust cap used to seal the female coupler when not connected.

- Type DP: Dust plug used to seal the male adapter when not connected.

Each type is selected based on specific task requirements.

Choosing the Right Camlock Fitting

Selecting the appropriate camlock fitting ensures a secure and efficient connection. Here are some factors to consider when choosing a camlock fitting:

- Material Compatibility: Ensure that the material of the camlock fitting is compatible with the liquids or gases being transferred to prevent corrosion and degradation.

- Size: The size of the fitting should match the size of the hoses or pipes being connected.

- Pressure and Temperature Ratings: The fitting should be able to withstand the pressure and temperature conditions of the application.

- Type: Choose the right type of camlock fitting based on the connection requirements.

- Quality: For greater reliability and durability, it is advisable to choose high-quality fittings from trustworthy manufacturers.

Camlock fittings are indispensable tools in the fluid transfer industry, providing a reliable, efficient, and cost-effective solution for connecting hoses and pipes. Their versatility and durability make them a top choice globally across industries. By understanding the different types of camlock fittings and considering factors such as material compatibility, size, pressure, and temperature ratings, users can select the appropriate fitting for their specific needs, ensuring a secure and leak-free connection.

In summary, camlock fittings enhance operational efficiency, ensure safety, and contribute to the seamless transfer of materials across numerous applications. Their role in supporting critical industries highlights their importance and underscores the need for users to understand their functionality, applications, and selection criteria comprehensively.