Air & Hydraulic Hose Coupling

Air and hydraulic hose couplings are essential components of industrial systems. They provide a flexible connection between two pieces of equipment, allowing them to be easily disconnected while still maintaining a secure seal. Couplings come in various sizes, shapes, and materials depending on the application they’re used for. In addition to providing a tight seal that prevents fluid leakage, air and hydraulic hose couplings also help reduce vibration and noise transmission throughout the system. By understanding different types of air and hydraulic hose couplings available as well as their benefits, applications, installation processes, common problems encountered with them – users can gain insight into how best to utilize these components within their own systems.

Overview of Air & Hydraulic Hose Coupling

These are essential components of industrial systems, providing a flexible connection between two pieces of equipment. Couplings come in various sizes, shapes, and materials depending on the application they’re used for. They help reduce vibration and noise transmission throughout the system while also preventing fluid leakage. They provide an important link between different parts of a complex machine – allowing them to work together efficiently without risking damage from wear or corrosion. Understanding their benefits, applications, installation processes as well as common problems encountered with them can help users make more informed decisions about how best to utilize these components within their own systems.

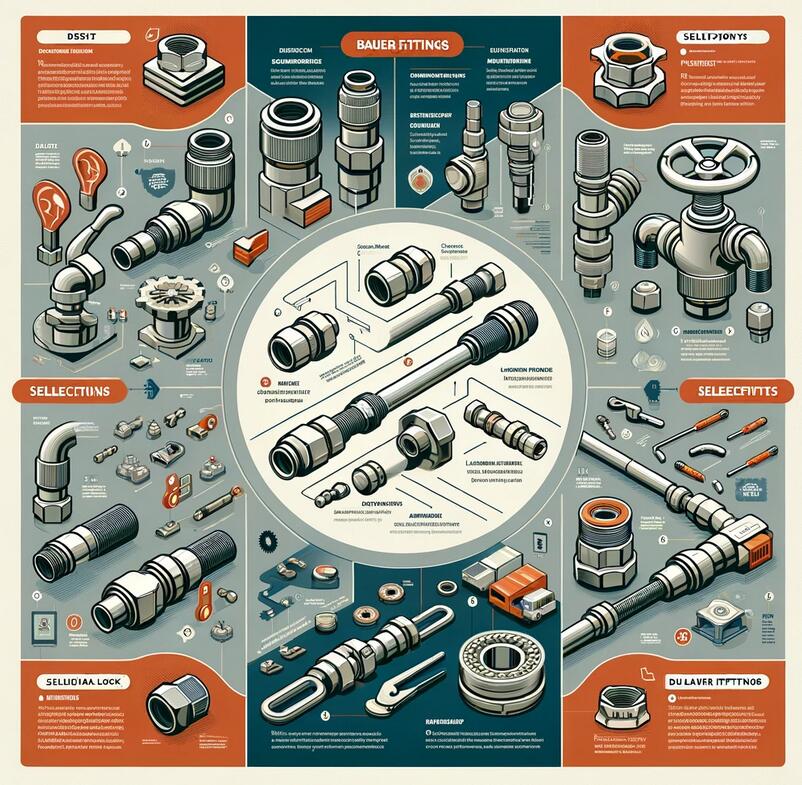

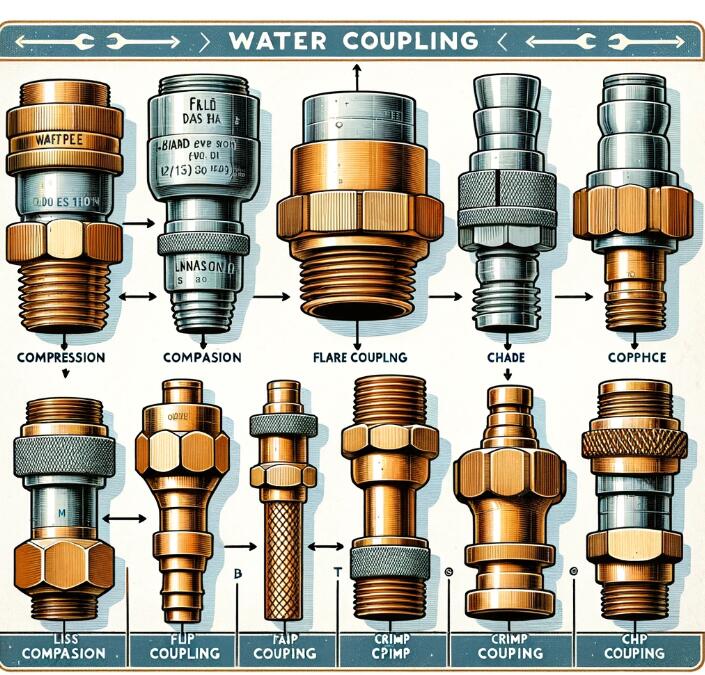

Types of Air & Hydraulic Hose Couplings

There are many types available for use in industrial systems. They come in a variety of sizes, shapes, and materials depending on the application they’re used for. Some common types include cam lock fittings, quick connect couplings, push-on fittings, reusable hose ends and flanges. Each type has its own benefits and disadvantages that should be considered when selecting the appropriate coupling for any given situation. Cam lock fittings provide quick connections with minimal effort while push-on fittings offer superior vibration protection due to their flexibility. Quick connect couplings are also easy to install but require additional safety measures such as locking pins or wire ties to ensure secure connections. Reusable hose ends allow users to easily replace worn parts without having to buy new ones while flanges provide an extra level of security by preventing accidental disconnection during operation.

Benefits of Using Air & Hydraulic Hose Couplings

They provide a secure, flexible connection between two pieces of equipment, allowing them to be easily disconnected while still maintaining a tight seal that prevents fluid leakage. Couplings also help reduce vibration and noise transmission throughout the system by absorbing any excess energy from the movement of parts. Additionally, these components are easy to install or replace when needed as well as being relatively inexpensive compared to other types of connections. With so many advantages offered by air and hydraulic hose couplings, it’s no wonder they’ve become such an integral part of modern industrial systems.

How to Install an Air & Hydraulic Hose Coupling

Installing an air and hydraulic hose coupling is a relatively simple process that requires minimal tools and equipment. It’s important to follow the manufacturer’s instructions to ensure a secure connection between two pieces of equipment, while also preventing fluid leakage. The steps involve measuring the length of the hose needed, cutting it to size, attaching clamps or ferrules to each end, connecting one fitting into the other side and tightening with wrenches or pliers until properly secured. Once complete, users should check for any leaks before operation can begin. With proper preparation and installation techniques, users can rest assured their systems are running safely and efficiently with no risk of damage from wear or corrosion.

Common Problems with Air & Hydraulic Hoses and Solutions

Air and hydraulic hoses are essential components for many industrial systems, providing a secure connection between two pieces of equipment. Despite their importance, it’s possible that air and hydraulic hose couplings can experience problems over time due to wear or corrosion. Common issues include leaks, cracking or splitting of the hose material, disconnection during operation and damage from vibration or pressure surges. Fortunately, there are steps users can take to prevent these problems as well as solutions available if they do occur. With proper maintenance and regular inspections, users can keep their systems running safely and efficiently with minimal disruption to production.

Best Practices for Maintaining an Air & Hydraulics System

Maintaining an air and hydraulics system is essential for safe, efficient operation. Proper maintenance should include regular inspections of all components, especially the hoses and couplings. It’s important to check for signs of damage such as cracking or splitting, as well as leakage or corrosion. Additionally, any loose clamps or fittings should be tightened to ensure a secure connection. With regular maintenance, users can rest assured their systems are running safely and efficiently with minimal disruption to production. By following these best practices, users can help extend the life of their air and hydraulics system and avoid costly repairs down the line.

Tips for Choosing the Right Size and Type of Fittings for Your Application

Choosing the right size and type of fittings for your air and hydraulic hose coupling application is essential for a successful installation. Different sizes, materials, and styles are available to meet a variety of needs, so it’s important to understand which option best fits your system’s requirements. Factors such as pressure rating, temperature range, and compatibility with other components should be taken into consideration when selecting fittings. Additionally, it’s important to ensure that the fitting you choose is properly sized in order to prevent leakage or damage from excessive pressure or vibration. With these tips in mind, you can make an informed decision about the right size and type of fitting for your application.

Air & Hydraulic Hose Coupling is an essential component for modern industrial systems, and proper installation and maintenance of these couplings are key to ensuring a secure connection. With the right size and type of fittings, users can prevent leakage or damage from excessive pressure or vibration while also extending the life of their machinery. Additionally, regular inspections should be conducted in order to identify any potential problems before they become costly repairs down the line. By following these best practices, users can ensure their air and hydraulics system is running safely and efficiently with minimal disruption to production.