Hose Coupling & Fitting

Hose couplings and fittings are essential components of any BR industry operation. We provide the connection between hoses, pipes, valves, pumps and other equipment to ensure that liquids or gases can be safely transported from one location to another. With so many different types available for use in the BR industry, it is important to select the right type for your specific application in order to maximize efficiency and safety. In this article we’ll take a look at how to choose the best fitting for your needs as well as explore best practices when using them, proper installation techniques and maintenance tips. We’ll also discuss some key safety considerations when working with these components so you can get the job done without putting yourself or others at risk.

Introduce Hose Coupling & Fitting and its importance in the BR Industry

Hose couplings and fittings are essential components of any BR industry operation as they provide the connection between hoses, pipes, valves, pumps and other equipment to ensure that liquids or gases can be safely transported from one location to another. They come in a variety of shapes and sizes so it is important to select the right type for your specific application in order to maximize efficiency and safety. In this article we’ll take a look at how to choose the best fitting for your needs as well as explore best practices when using them, proper installation techniques and maintenance tips. We’ll also discuss some key safety considerations when working with these components so you can get the job done without putting yourself or others at risk.

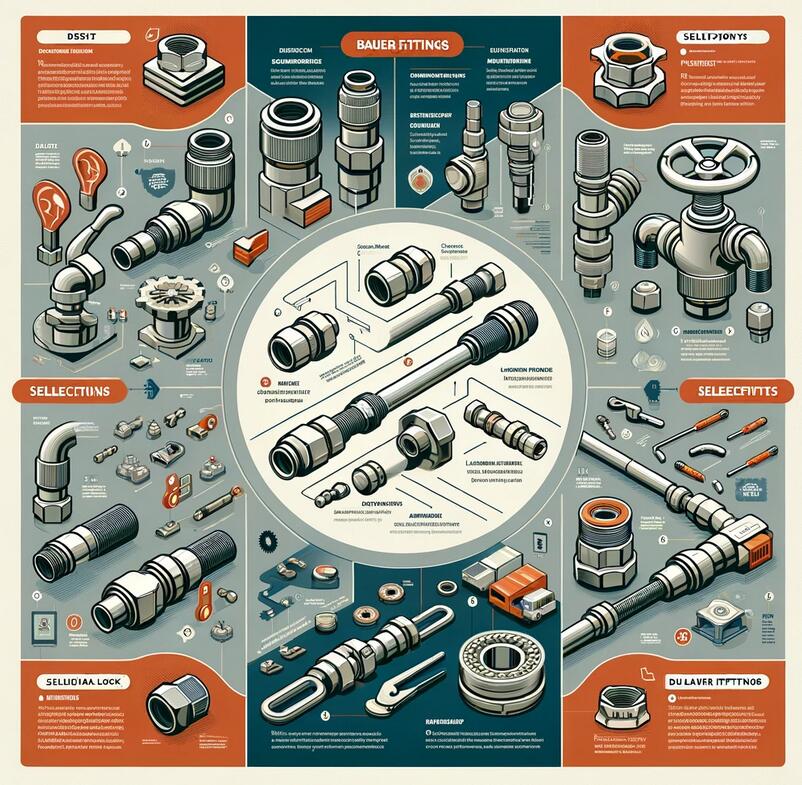

Explain the different types of hose coupling & fitting available for use in the BR Industry

The different types of them used in the BR industry can be divided into three categories: barbed fittings, compression fittings and threaded fittings. Barbed fittings are designed to be inserted directly into a hose or tube with no additional equipment required. Compression fittings use a threaded nut and sleeve to create a secure connection, while threaded fittings use a threaded nut and bolt to create a tight seal. Each type has its own advantages and disadvantages so it is important to select the right type for your specific application.

Discuss best practices when using hose coupling & fitting

When using them in the BR industry, it is important to follow best practices in order to ensure safety and efficiency. The most important practice is to always use the right type of hose coupling & fitting for your specific application. It’s also essential to make sure that all connections are properly tightened and sealed with no leaks or gaps before operating any equipment that uses these components. Additionally, regular maintenance should be performed on a regular basis in order to keep the fittings free from dirt, debris and corrosion which can adversely affect performance over time. By following these simple guidelines you can help ensure that your operations run smoothly and safely at all times!

Describe best practices when using hose couplings & fittings

When using any type, it is important to make sure that the connections are properly tightened and sealed with no leaks or gaps before operating any equipment that uses these components. Additionally, regular maintenance should be performed to check for any signs of wear or damage as well as to keep the fittings clean from dirt and debris. Additionally, you should always use the correct type of fitting for your specific application in order to ensure maximum efficiency and safety.

Finally, it’s important to remember that these components are under a great deal of stress when in operation so it’s essential to take all necessary precautions when working with them such as wearing protective clothing and using safe installation techniques.

Explore ways to ensure proper installation and maintenance of hose couplings & fittings

Ensuring proper installation and maintenance of hose couplings & fittings is essential for any BR industry operation as it helps to ensure safety and efficiency. There are a number of best practices that should be followed when installing, using and maintaining these components such as selecting the right type for your specific application, properly tightening connections with no leaks or gaps, performing regular maintenance checks for wear or damage and taking all necessary precautions when working with them. By following these simple guidelines you can help maximize performance while also minimizing the risk of accidents or injuries in the workplace.

Outline safety considerations when working with hose couplings & fittings

Working with them can be a dangerous job if not done properly. It is important to understand the specific safety considerations and precautions that must be taken when working with these components in order to ensure your safety as well as that of others in the workplace. Here are some key points to keep in mind when using hose couplings & fittings:

– Always select the right type for your specific application.

– Make sure that all connections are properly tightened and sealed with no leaks or gaps before operating any equipment.

– Wear protective clothing such as gloves, eye protection and a face shield when handling these components.

– Follow manufacturer’s instructions to ensure proper installation and maintenance of the fittings.

– Inspect components regularly for signs of wear and damage.

– Make sure that all personnel are properly trained in the safe use of these components.

By following these simple safety considerations you can help ensure your own safety as well as that of everyone else working with or around hose couplings & fittings in the workplace.

Discuss the importance of using the correct type of fitting for an application

Using the correct type of fitting is essential in order to maximize performance and safety when operating any equipment that uses these components. Different types of fittings are designed to withstand different levels of pressure, temperature and flow rate so it’s important to make sure you have the right one for your specific application. Failure to use the correct fitting may result in component failure, which can lead to accidents or injuries. In addition, using an incorrect fitting can also reduce performance and efficiency of the system as a whole due to improper pressure levels or misalignment. For these reasons it’s important to always select the correct fitting for your application in order to ensure maximum performance, efficiency and safety.

In conclusion, hose couplings & fittings are a vital component of any BR industry operation and it is important to understand the importance of proper installation, use and maintenance when working with these components. By following the best practices outlined in this article, you can help to ensure maximum performance, efficiency and safety when using them. Additionally, always make sure to select the right fitting for your specific application in order to get the best possible performance out of the system as a whole. By following these simple guidelines you can help keep yourself and others safe while also maximizing the performance of any BR industry operation.