PEX Straight Pipe

Overview of PEX Straight Pipe

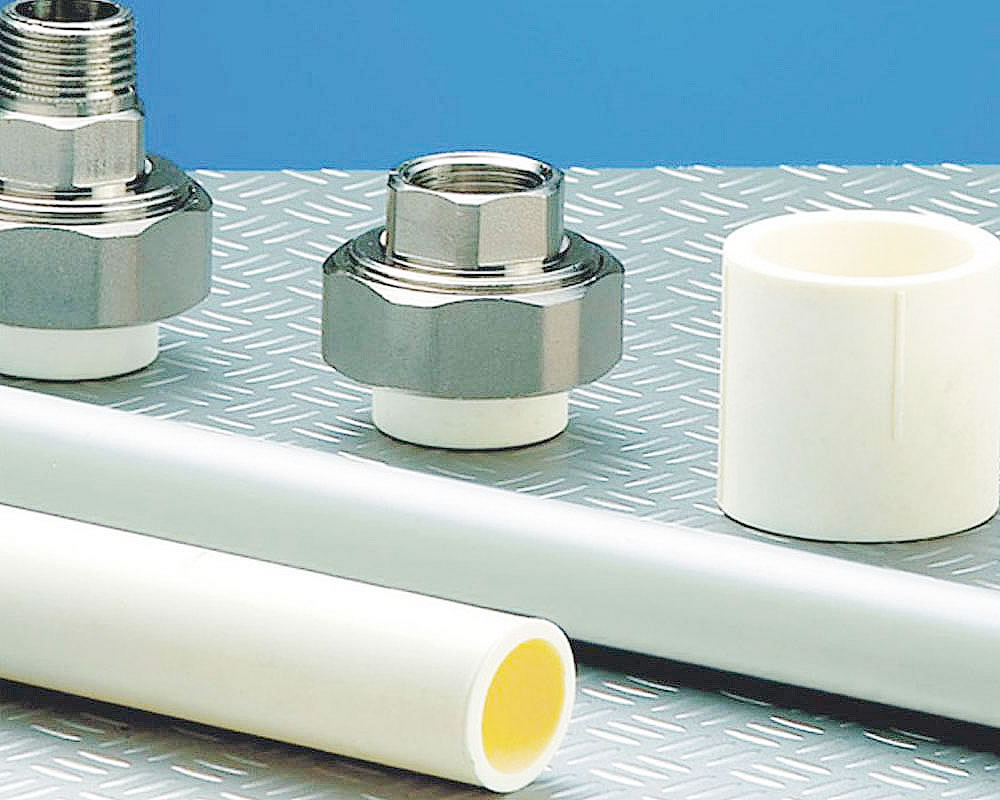

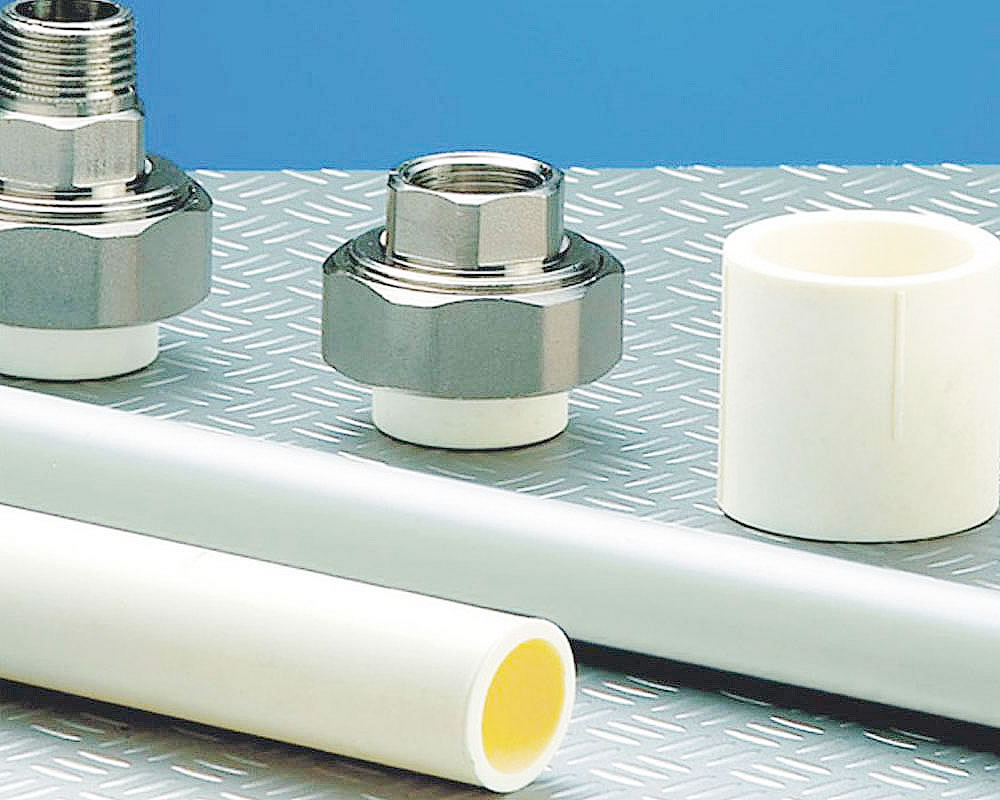

PEX Straight Pipe is a type of pipe used in plumbing and heating systems. It is made of cross-linked polyethylene (PEX), which offers superior strength, flexibility, and heat resistivity compared to traditional polyvinyl chloride (PVC) pipes. It also has excellent chemical resistance and can withstand higher temperature and pressure than other pipe materials. Additionally, it is easy to work with, making it a popular choice for many plumbing projects.

Benefits of Using PEX Straight Pipe

PEX Straight Pipe offers a number of advantages compared to other plumbing materials. It is much more lightweight than metal pipes, making it easier to handle and install in tight spaces. It is also very durable, with an expected lifespan of 50 years or more when used correctly. Additionally, it can be bent around corners and maneuvered around obstacles without the need for special connectors or fittings, saving time and money on installation costs. The flexibility of PEX Straight Pipe also makes it resistant to freezing temperatures and cracking due to expansion in colder climates. Finally, it has excellent thermal insulation properties, allowing it to maintain desired temperature levels with minimal energy consumption.

Types of PEX Straight Pipe

1. PEX-A Straight Pipe: This type of PEX pipe is made with a special process that allows for flexibility and strength suitable for pressurized applications.

2. PEX-B Straight Pipe: This type of pipe is made with a peroxide crosslinking method and offers high performance when it comes to temperature resistance, chemical resistance, impact strength, and pressure ratings.

3. EVOH PEX Straight Pipe: This type of pipe contains an oxygen barrier layer which helps to reduce the flow rate of oxygen through the pipes, making it an ideal choice for radiant floor heating systems.

4. PE-RT (Polyethylene Raised Temperature) Straight Pipe: This type of pipe offers improved thermal properties compared to other types of straight pipes due to its higher melting point and increased flexibility at lower temperatures.

5. Corrugated PEX Straight Pipe: This type of pipe offers improved flexibility, making it easier to install in tight spaces and around corners.

Installation Tips for PEX Straight Pipe

1. Wear gloves when handling PEX Straight Pipe as it is susceptible to cutting and scratching.

2. Use a pipe cutter or saw to make precise cuts when installing the piping system.

3. Before attaching fittings, use sandpaper or rubbing alcohol to clean the outside of the pipe and inside of the fitting for a secure connection between components.

4. When using compression type fittings, tighten them by hand first before applying additional force with a wrench or other tool in order to prevent over-tightening which may damage the fitting or cause leaks in your system.

5. Use insulated clamps around exposed pipes – especially if they are located outdoors – in order to protect from freezing temperatures that can crack pipes during winter months .

6. Follow local building codes and ordinances for correct installation practices specific to your area when completing any plumbing project involving PEX Straight Pipe

5. Common Issues with PEX Straight Pipe and How to Avoid Them

PEX Straight Pipe is generally a reliable and durable plumbing material. However, there are some common issues that can arise when using these pipes. For instance, improper installation of the piping system will often lead to leaks due to poor connections between components. This can be avoided by ensuring that fittings are properly tightened with a wrench after being hand-tightened. If a pipe is frozen, it can crack due to the expansion of water inside the pipes. This issue can be avoided by using insulated clamps around exposed pipes located outdoors and taking preventative measures in colder climates. Finally, using too small of a diameter pipe in your system can lead to reduced flow rate and increased energy consumption. It’s best to consult with a professional plumber or building engineer when deciding which pipe size is most appropriate for your needs.