Quick Coupler Types

Quick couplers are essential components in a variety of industrial systems, providing the ability to quickly and easily connect and disconnect pipes or tubes without losing pressure or fluid. There are several types of them available, each with its own benefits and features. We’ll discuss the different types of them, their advantages, how to install them correctly, what considerations to make when choosing a type for your system, some maintenance tips for your quick coupling system and frequently asked questions about using these products.

Overview of Quick Coupler Types

They are an important part of any industrial system, providing a way to quickly and easily connect and disconnect pipes or tubes without losing pressure or fluid. There are several types of them available, each with its own set of features and benefits. In this article, we’ll discuss the different types of them, their advantages and how to install them correctly. We’ll also look at what considerations should be made when choosing a type for your system as well as some maintenance tips for your quick coupling system and frequently asked questions about using these products.

Benefits of Using Quick Couplers

They offer many advantages over traditional connections, such as increased safety and convenience. They provide a secure and leak-proof connection, eliminating the need for costly equipment, tools, or time-consuming manual work. They are also designed to be used multiple times, which helps reduce downtime by eliminating the need to replace parts every time a connection is made or broken. Finally, they help reduce the risk of spills and other environmental hazards by eliminating human error in connecting pipes or tubes.

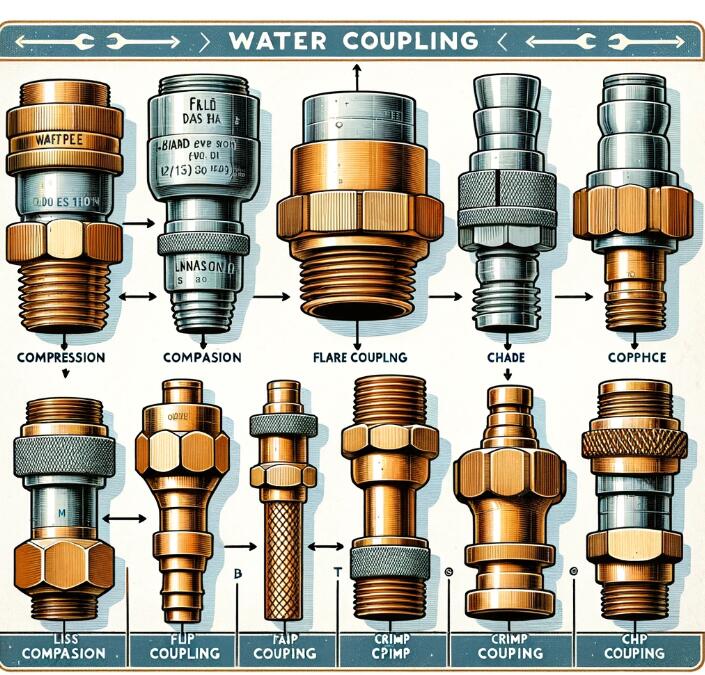

Different Types of Quick Couplers

They are an essential component in a variety of industrial systems, providing the ability to quickly and easily connect and disconnect pipes or tubes without losing pressure or fluid. There are several types available, each with its own benefits and features. In this article, we’ll discuss the different types of them, their advantages, how to install them correctly, what considerations to make when choosing a type of quick coupler for your system as well as some maintenance tips for your quick coupling system and frequently asked questions about using these products.

How to Install a Quick Coupler

Installing a quick coupler is an important part of any industrial system, as it provides the ability to quickly and easily connect and disconnect pipes or tubes without losing pressure or fluid. Knowing how to install it correctly can help ensure that your system runs smoothly and efficiently, while also reducing downtime caused by incorrect installation. In this article, we’ll discuss the different steps involved in installing it, including preparation of the pipe or tube ends, selection of the right type of coupling for your application and proper connection techniques. We’ll then provide some tips on ongoing maintenance to keep your quick coupling system running properly.

What to Consider When Choosing a Quick Coupler Type

When selecting the type for your industrial system, there are several factors to consider. The most important factor is the application. Different types may be better suited for different applications and environments; therefore, it’s important to choose one that meets your specific needs. Additionally, you should consider the size of the pipes or tubes you’ll be connecting with the coupler as well as any other requirements such as pressure rating and flow rate. Finally, it’s important to take into account safety considerations when choosing a type, make sure that all parts are properly rated and certified for use in hazardous areas if necessary.

Maintenance Tips for Your Quick Coupler System

Maintenance of a quick coupler system is essential for proper operation and prolonged use. It is important to inspect the system regularly for any signs of wear or damage to prevent any potential problems from arising. When inspecting the couplers, check all components such as seals, O-rings and gaskets for any signs of wear or damage and replace them as necessary. Additionally, be sure to clean the coupler system on a regular basis to remove any dirt or debris that might get trapped in the connection. Finally, make sure to periodically lubricate the components of your system to ensure smooth operation. By following these simple maintenance steps, you can help keep your system running smoothly and efficiently.

FAQs About Quick Coupling Systems

A FAQ section regarding quick coupling systems is an important part of any industrial system. This section covers questions such as, what are the different types of quick couplers available and how should they be installed correctly? What considerations should be taken into account when choosing a type of them for your application and what maintenance steps should be taken to keep your system running properly? By answering these frequently asked questions, you can ensure that your industrial system is installed and maintained correctly.

Knowing the different types of quick couplers available and how to install them correctly are important steps in ensuring that your industrial system runs smoothly and efficiently. Additionally, taking into account the factors necessary for choosing a quick coupling type and taking the necessary maintenance steps can help extend the life of your system. With these tips in mind, you can be sure that your quick coupler system is a reliable one.