Quick Coupling Joints

What Is A Quick Coupling Joint?

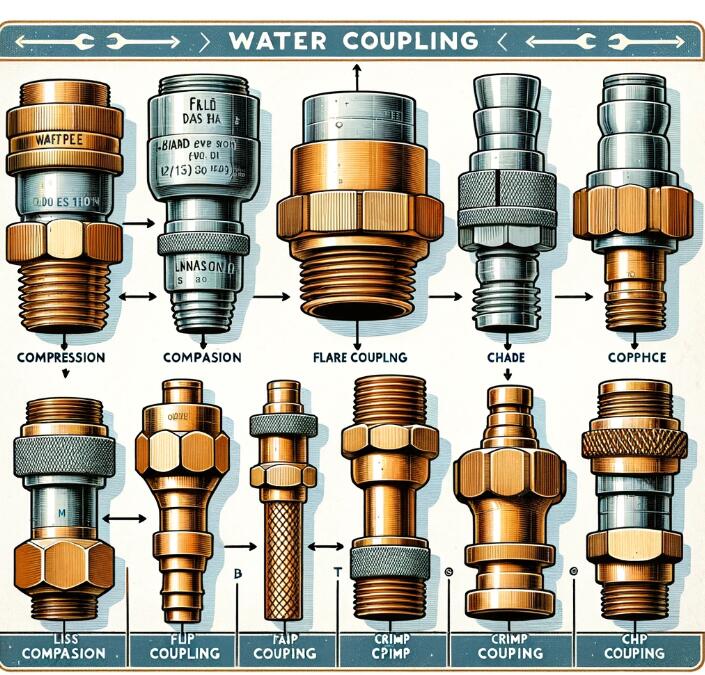

A quick coupling joint, often called a quick coupler, is a mechanical tool that offers an easy, fast, as well as sure way to connect and disconnect any gas-like or fluid line frequently. A quick coupling joint composes of two parts, a socket, and a plug. A socket is a female half while the plug is a male half. When linked properly, the parts cover and lock the joint efficiently to contain pressures inside and, at the same time, resist tensile pressured, which likely to draw the joint apart.

As a whole, the benefits of quick coupling joint are divided into various categories such as:

Save effort and time: by the quick coupling disassembly as well as the connection of oil, the action is very simple, save manpower and time.

Fuel Effective: Broken oil, this product on the single-way valve can be closed liquid, and it will not flow out, thus avoiding the loss of oil pressure.

Environmental Security: With this device, the oil stop from spilling and keep the environment safe and sound.

Easy to Transport: This is easy to transport

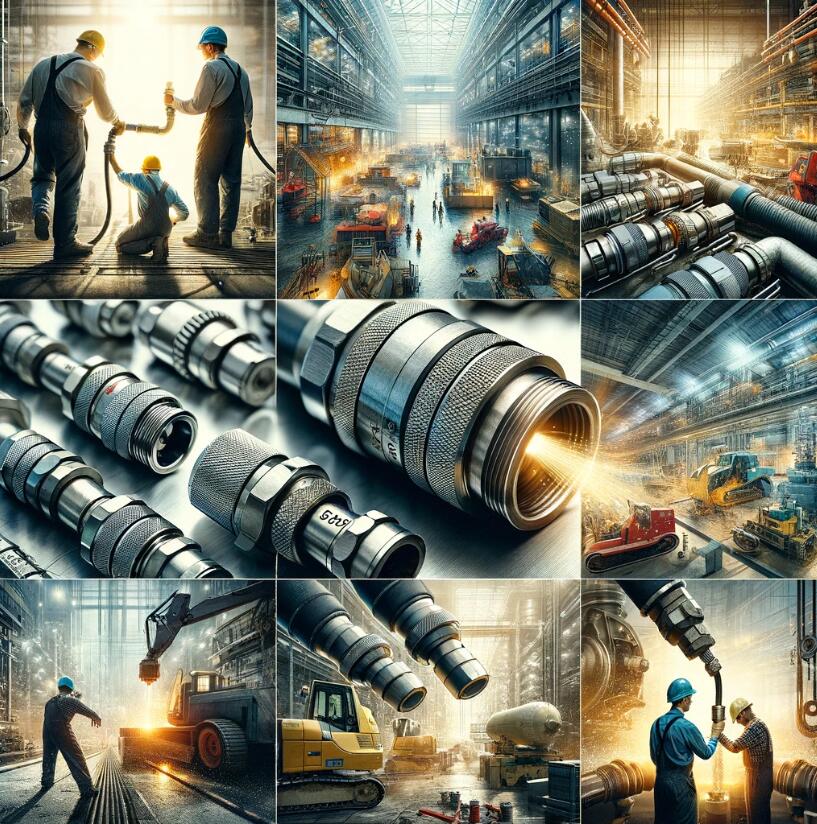

Uses

The quick coupling joints are utilized in the machine for many purposes. The main or primary job is to transfer power from one part to another. Other popular uses take account of:

- To change the vibration features of go around units.

- Connect or link driving as well as the driven portion

- Introduce security and protection

- To lessen the transmission of shock load from one shaft to the next.

- Slip once overload happens

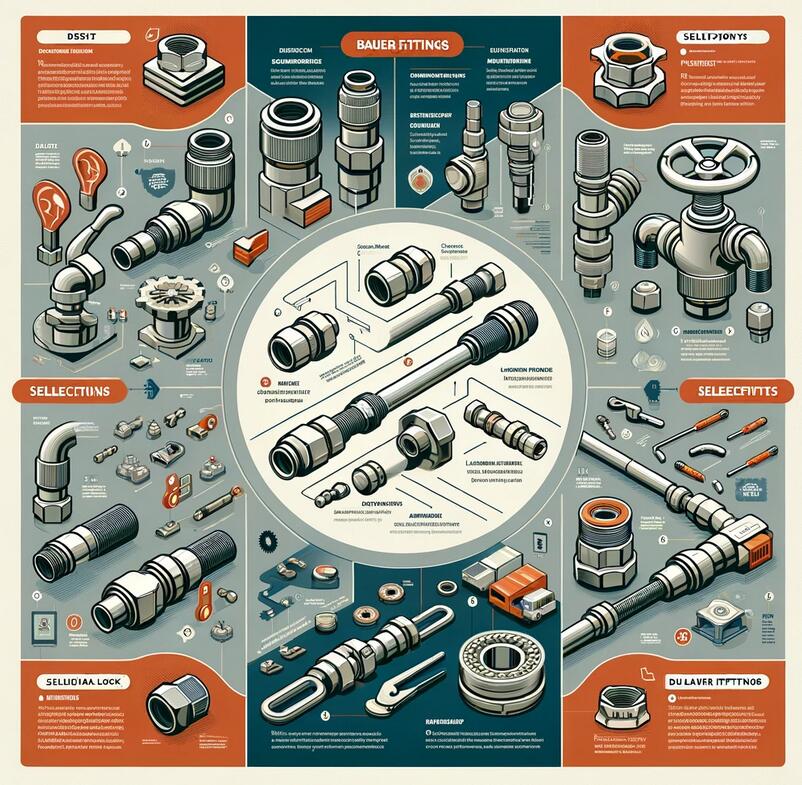

Features of Our Quick Coupling Joints

We offer a high quality quick coupling joint that is packed with amazing and state of the art features such as:

Able to accommodate angular deflection between tubes that makes for a faster and easier installation. This also enables the movement of the pipeline like the ground settlement.

There is no need for a special fitting.

There is also no requirement for special devices to use; all you need is a torque wrench and deep reach socket.

It can accommodate additional space for contraction or expansion for every fitting. This lessens the demand for supplementary expansion bellows or joints.

How to Maintain Quick Couplings Joints

Quick couplings joints maintenance needs a regularly scheduled check or examination of every coupling. It takes account of:

- Doing visual assessments

- Checking for indications of fatigue or wear

- Cleaning the quick couplings joint on a regular basis

- Checking as well as changing lubricant on a frequent once it’s lubricated. The maintenance is highly advisable per year for many couplings and more often for couplings in unfavorable settings or demanding working conditions. Manuscript the maintenance is done on every coupling, together with the data.

On the other hand, even with regular maintenance, this can also fail. Some reasons for its failure take account of:

- Poor selection of coupling

- Improper setup

- Operation beyond style in capabilities

The best way to boost the life of your quick coupling joints is to know what caused its failure and then to correct it before setting up a new one. There are external indications, which show the possible failure of your quick coupling joints that takes account of the following:

- Abnormal noise, which includes squealing, chattering as well as screeching

- Too much wobble or vibration

- Failed covers or seals shown by the leakage of the lubricant or contamination

For more information about our quick coupling joints and how we can help you, please feel free to call our customer hotline number. We are more than happy to help!