Storz Fitting

Are you looking for a reliable and efficient way to connect two pieces of hosing or tubing? If so, then the Storz fitting is the perfect solution. The fitting is a type of connector used in BR industry that allows for quick connection and disconnection without tools. It is designed to be leak proof and provide an airtight seal between two hoses or tubes with minimal effort. In this article, we will discuss the various types available on the market, how they work, their benefits, proper installation techniques as well as safety considerations when working with them.

Introducing the Storz Fitting – What is it and How Does it Work

The Storz fitting is a type of connector used in BR industry that allows for quick connection and disconnection without tools. It consists of two parts, the male end which features a conical shape with external threads and the female end which has an internal threading. When connected together, they create an airtight seal that prevents leaks. It works by pushing the male end into the female part until it locks into place securely. To disconnect them, simply pull up on the collar located at the base of each side to release them from one another. This makes installation and removal extremely fast and easy while providing superior leak protection compared to other types of connectors available on the market today.

Benefits of Using a Storz Fitting in BR Industry

The Storz fitting provides numerous benefits to users in BR industry. It is designed for quick connection and disconnection without tools, making it ideal for applications where frequent assembly or disassembly is required. Its airtight seal prevents leaks and ensures a secure connection between two hoses or tubes. Additionally, it offers superior corrosion resistance compared to other types of connectors on the market today, providing long-term reliability in even harsh industrial environments. Finally, since no special tools are needed for installation or removal, maintenance costs associated with using this type of connector are significantly lower than those associated with other types of fittings available.

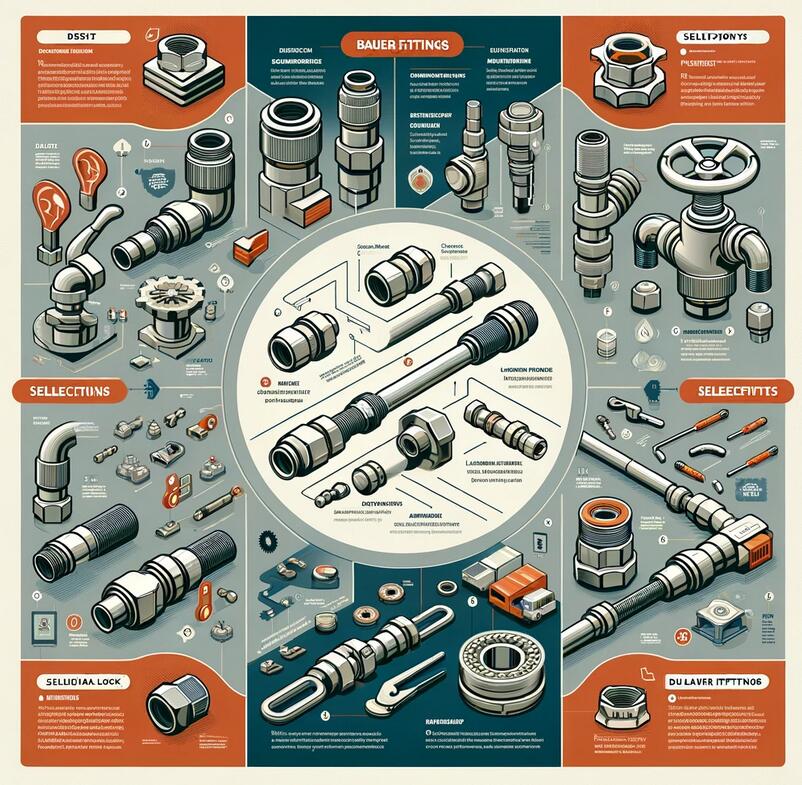

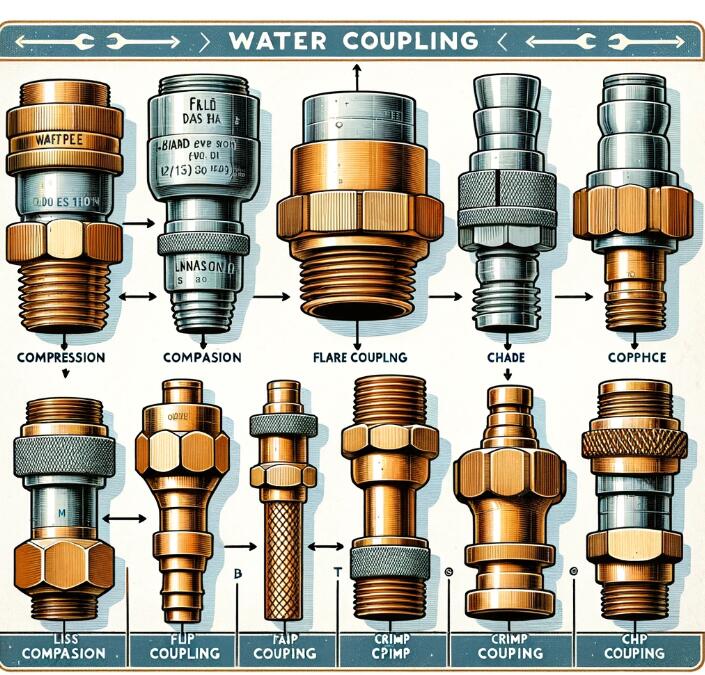

Different Types of Storz Fittings Available on the Market

When it comes to connecting two pieces of hosing or tubing, it is one of the most reliable and efficient solutions available on the market today. It consists of a male end with an external threading and a female end with an internal threading that can be quickly connected and disconnected without tools. There are several different types available which vary in size, material, and design to accommodate various applications in BR industry.

How to Properly Install a Storz Fitting for Maximum Efficiency

Proper installation is essential in order to ensure maximum efficiency and reliability. The Storz fitting consists of two parts, the male end which features a conical shape with external threads and the female end which has an internal threading. When connected together, they create an airtight seal that prevents leaks. Installing these fittings correctly requires following certain steps to ensure proper alignment and maximum efficiency. In this article, we will discuss how to properly install it for maximum efficiency as well as safety considerations when working with them.

Common Problems with Installing a Storz Fitting and Solutions to Fix Them

Common problems with installing can include difficulty in aligning the two parts to create an airtight seal, working with hoses or tubes of differing diameters, and improper threading of the male and female ends. To ensure a proper installation and avoid any issues, it is important to use the correct tools for assembly as well as be careful to properly align the two components. Additionally, when working with hoses or tubes of different diameters, it is important to select a Storz fitting that will accommodate them both evenly. Finally, ensuring the male and female ends are threaded correctly is key for preventing any leaks from occurring.

Safety Considerations When Working with a Storz Fitting

When working with a Storz fitting, it is important to take the necessary safety precautions in order to ensure that you are protected from any potential risks. The fitting consists of two parts: a male end and a female end, both of which need to be properly secured for an airtight seal. It is also essential to use the proper tools when assembling or disassembling these fittings as they can become damaged easily if handled incorrectly. Additionally, when working with hoses or tubes of different diameters it is important to select a fitting that will accommodate them both evenly in order to avoid any leaks from occurring during installation. By following these guidelines and taking the necessary safety measures, you can make sure your project is successful and safe.

Storz fittings are one of the most reliable and efficient solutions available on the market today when connecting two pieces of hosing or tubing. They offer superior corrosion resistance compared to other types of connectors as well as require no special tools for installation or removal, making maintenance costs significantly lower than those associated with other types of fittings. By following the necessary steps for proper installation, you can ensure maximum efficiency and reliability from your Storz fitting as well as take all necessary safety measures when working with it to prevent any potentially hazardous situations. With these tips in mind, you can rest assured that your project will be successful and safe.