The Ultimate Guide to Flanged Camlock Fittings: Design, Use, and Value

When it comes to industrial fittings, making the right choice is crucial. It impacts the efficiency of your operations, safety standards, and overall productivity. Today, we’re diving into the world of flanged camlock fittings – a versatile and reliable choice gaining popularity across various industries.

Understanding Camlock Fittings

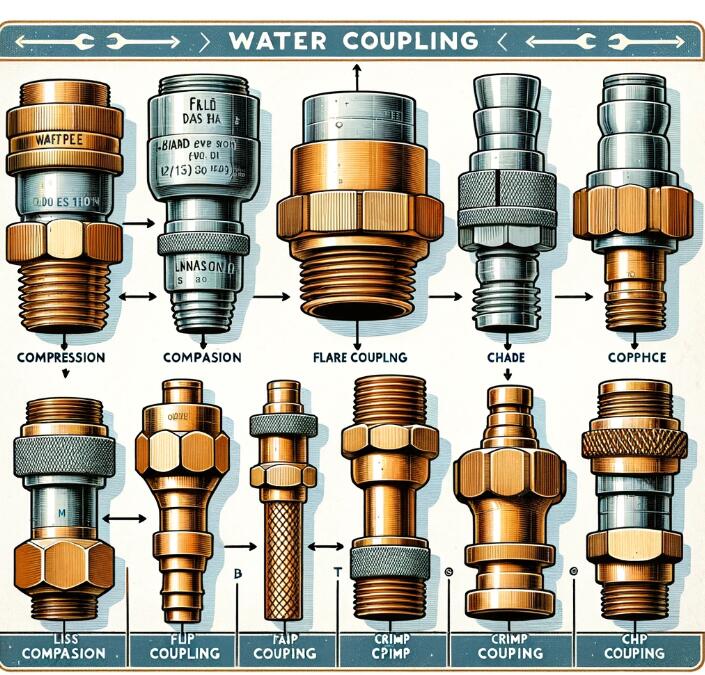

Before we delve into flanged camlock fittings, let’s understand what camlock fittings are. Also known as cam and groove couplings, these are a type of fitting used to connect hoses and pipes in various applications. They are renowned for their quick and easy use, making them a popular choice for multiple industries, including manufacturing, chemical processing, and firefighting.

Camlock fittings come in various types, each designed to suit a specific purpose. Some common types include Type A (Male Adapter), Type B (Female Coupler), and Type C (Hose Shank). But, our key focus today will be on Type D, better known as Flanged Camlock Fittings.

Deep Dive into Flanged Camlock Fittings

Flanged camlock fittings come with a flanged end that allows for a secure connection, especially in high-pressure or large volumes applications. Their unique design enhances their sealing capabilities, making them an excellent choice for systems that require a robust, leak-proof connection.

One of the key advantages of flanged camlock fittings is their ease of use. Their design allows for quick and tool-free connection and disconnection, leading to significant time savings, especially in applications that require frequent hose or pipe changes. They also offer high durability, thanks to their sturdy construction and the ability to withstand harsh conditions, making them a cost-effective long-term investment for businesses.

Application of Flanged Camlock Fittings

Flanged camlock fittings find their use in a wide array of industries. They’re popular in the petroleum industry and used for connecting hoses during fuel transfer. In the chemical industry, their high resistance to corrosion makes them a reliable choice for transporting corrosive substances. They’re also found in agriculture for irrigation systems, water supply, and waste management.

Despite their extensive use in heavy-duty industrial applications, flanged camlock fittings aren’t limited to these. They’re also used in residential settings for connecting hoses in gardens and cleaning tasks, thanks to their easy-to-use nature and versatility.

How to Choose the Right Flanged Camlock Fittings

Choosing the right flanged camlock fitting for your application can be challenging, given the range of options available. Several factors should be considered, such as the type of fluid being transported, the working pressure, and the environmental conditions. Additionally, the size of the fitting, the material it’s made from, and the type of connection required (threaded or flanged) are also essential considerations.

Material selection is especially critical since it impacts the fitting’s durability, resistance to corrosion, and ability to handle the transported substance’s temperature. Common materials include stainless steel, aluminum, brass, and polypropylene, each with pros and cons.

Installing and Maintaining Flanged Camlock Fittings

Flanged camlock fittings are known for their user-friendly design. The installation often requires only the proper alignment of the cam and groove before the cam levers are locked into place. However, while the installation may seem straightforward, following the manufacturer’s guidelines closely is crucial to ensure a safe and secure connection.

Maintenance is another key aspect of ensuring the longevity and optimal performance of your flanged camlock fittings. Regular checks for any signs of wear, damage, or leakage are essential. Over time, seals might wear out, requiring replacement. Regular cleaning is also critical, particularly in fittings used for transporting corrosive or sediment-laden fluids.

Case Study: Impact of Quality Flanged Camlock Fittings on Business Efficiency

To better understand the tangible benefits of flanged camlock fittings, let’s consider the case of a mid-sized chemical processing plant. They faced recurrent issues with their previous hose connections, leading to frequent leaks, maintenance shutdowns, and increased operational costs.

Given their reputation for secure and leak-proof connections, the plant decided to switch to flanged camlock fittings. The result was immediate – they saw a significant reduction in leak incidents, leading to fewer disruptions and reduced maintenance costs. Furthermore, the quick connect-disconnect feature saved precious time during hose changes, increasing overall operational efficiency. This example illustrates how investing in high-quality flanged camlock fittings can deliver substantial returns.

Where to Buy Quality Flanged Camlock Fittings

Choosing the right supplier is critical when investing in flanged camlock fittings. Look for a supplier known for quality products, excellent customer service, and reliable delivery. It is advantageous to locate a supplier who can provide various materials and sizes to ensure the perfect match for your unique requirements.

Before finalizing a supplier, ask about their manufacturing standards and quality control processes. Online reviews and testimonials can provide useful insights into other customers’ experiences. Also, ask for references or case studies to verify their claims.

Future Trends in Flanged Camlock Fittings

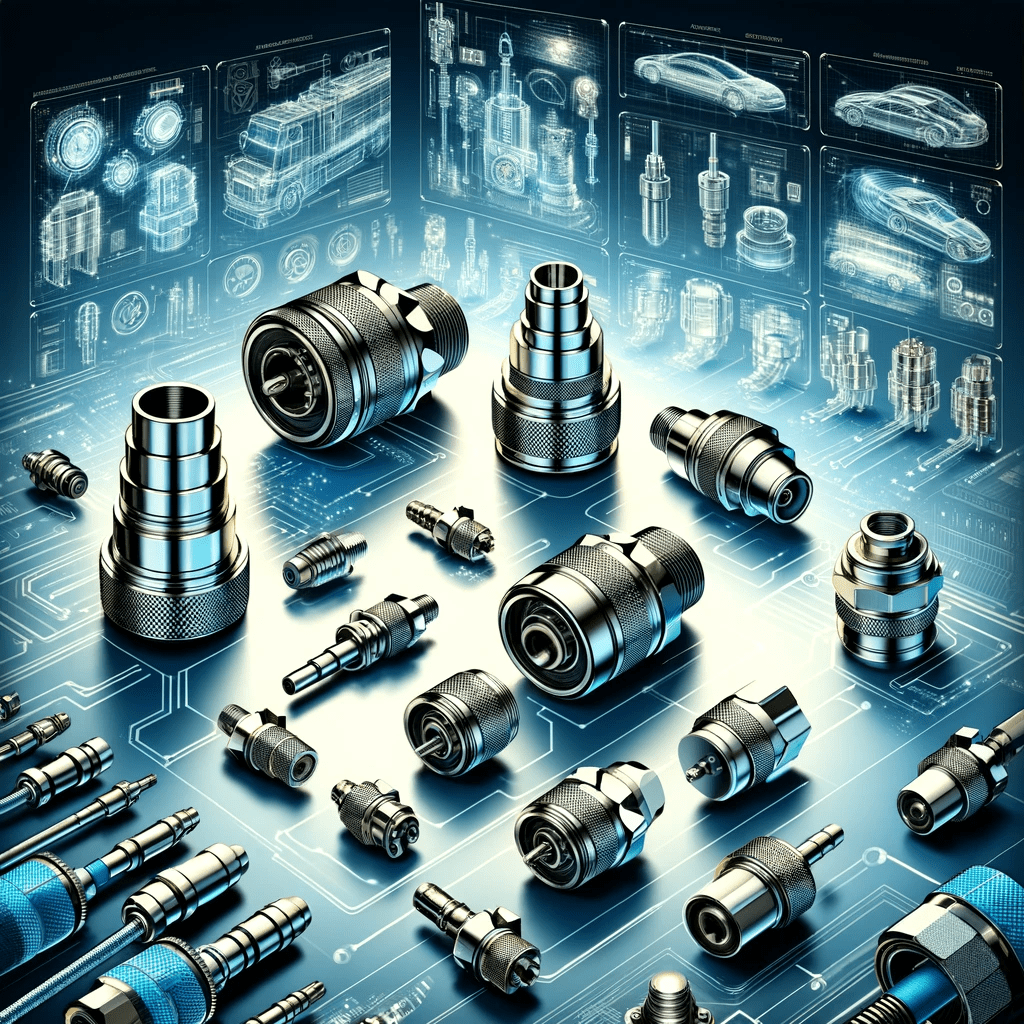

The flanged camlock fittings market is expected to evolve with advancements in materials and design technologies in the coming years. Innovations might focus on improving durability, resistance to varying pressure levels, and compatibility with a broader range of substances. Furthermore, manufacturers might invest in more eco-friendly materials and production processes as environmental sustainability becomes a priority.

Digital technologies also play a part in the evolution of camlock fittings. For instance, smart fittings equipped with sensors could monitor system parameters in real time, helping predict potential issues and maintenance needs before they lead to significant problems.

Flanged camlock fittings are an integral component in various applications across various industries. Their secure, easy-to-use design and high durability make them an invaluable tool for any business requiring robust and reliable hose or pipe connections.

Choosing the right flanged camlock fitting requires careful consideration of various factors, from the nature of the fluid being transported to the operating conditions. With the right selection, proper installation, and regular maintenance, these fittings can significantly enhance operational efficiency and cost-effectiveness.

The future looks promising for flanged camlock fittings, with advancements in technology likely to bring further improvements in design and functionality. As we move forward, we will focus on delivering high-quality, reliable, and sustainable solutions for all users.