Threaded Camlock

Threaded camlocks are essential components of many industrial systems, from manufacturing plants to oil refineries. They provide a secure and reliable connection between two pipes or hoses, allowing liquid or gas to flow between them without the risk of leakage. They are available in different sizes and materials, depending on the application. In this article, we’ll discuss the basics of them including their benefits, types available, installation instructions and best practices for maintenance. We’ll also look at some common problems that can arise when installing or maintaining these devices.

Overview of Threaded Camlock

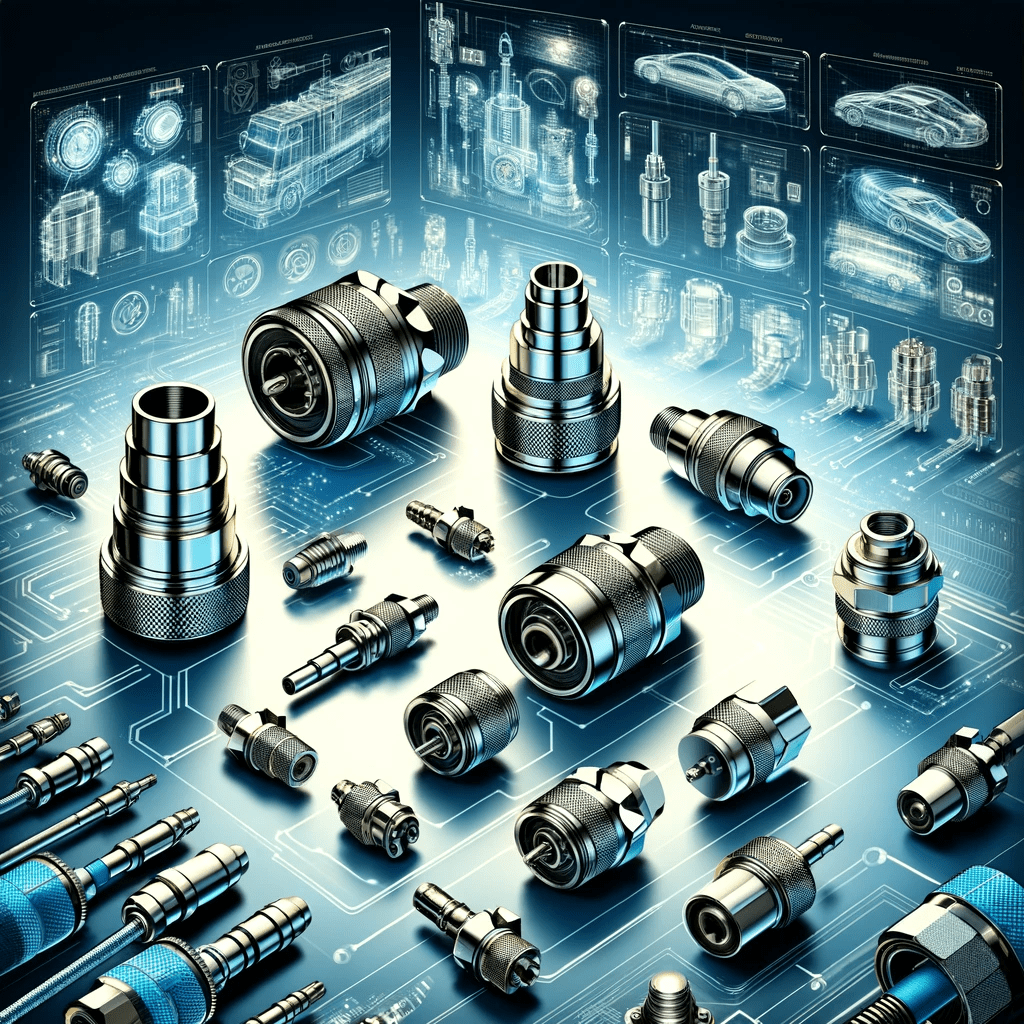

Threaded camlocks are a type of quick-connect device that is used to securely and reliably connect two pipes or hoses in order to allow liquid or gas to flow between them without the risk of leakage. They can be found in many industrial systems, from manufacturing plants to oil refineries, and are available in different sizes and materials depending on the application. They provide numerous benefits such as easy installation, safe operation and reliable connection – making them an essential component for any industrial system. In this article we’ll discuss the basics of them including their types available, installation instructions and best practices for maintenance. We’ll also look at some common problems that can arise when installing or maintaining these devices.

Benefits of Using Threaded Camlock

Using threaded camlocks offers many benefits that make them an essential component for any industrial system. The most notable advantages include easy installation, secure connection, safe operation and reliable connection. With them, it is easier to connect two pipes or hoses together quickly and securely with minimal effort. This also allows liquid or gas to flow between the two connections without the risk of leakage. Additionally, they are generally easy to maintain and relatively inexpensive, making them a cost-effective option for many applications.

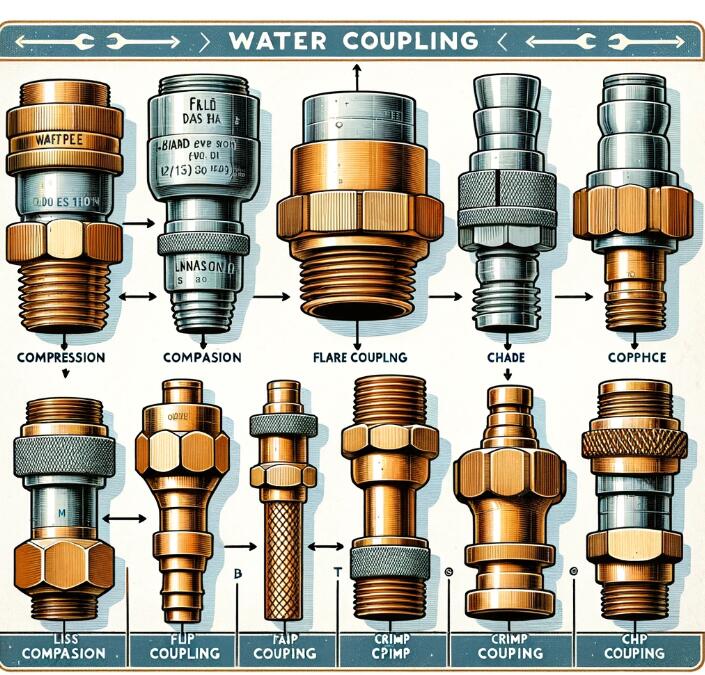

Types of Threaded Camlocks Available

They are available in a variety of sizes and materials, making them suitable for many different applications. The most common types include aluminum, brass, stainless steel and polypropylene camlocks. Each type has its own benefits depending on the application – aluminum is lightweight and corrosion-resistant while brass is strong and durable. Stainless steel provides excellent resistance to high temperatures while polypropylene offers superior chemical compatibility. Additionally, some can be customized with specialty seals or gaskets to ensure an even tighter seal between two pipes or hoses.

How to Install

Installing a threaded camlock is an essential part of setting up any industrial system. They are quick-connect devices that provide a secure and reliable connection between two pipes or hoses, allowing liquid or gas to flow between them without the risk of leakage. Installing these devices requires some knowledge and skill, but with the right instructions it can be done quickly and efficiently. In this article, we’ll discuss how to install them including what materials you need, installation tips and best practices for maintenance. With this information in hand, you’ll be able to easily set up your industrial system with confidence!

Best Practices for Maintaining a Threaded Camlock

Maintaining is essential for ensuring that they continue to function safely and securely for years to come. It is important to regularly check the condition of the threads on both the camlock and its mate, as well as inspecting the seals and gaskets for any signs of wear or damage. Additionally, it is important to lubricate the threads and seals regularly to ensure a tight seal. If any parts of the camlock are damaged, it is important to replace them as soon as possible. Following these simple steps will help you maintain your camlocks in top condition for years to come!

Common Problems with Installing or Maintaining

When it comes to installing or maintaining, there are a few common problems that can arise. For example, if the threads on either the camlock or its mate are worn out, this can lead to an unreliable connection and possible leakage. Additionally, seals and gaskets can become damaged due to age or wear-and-tear which also leads to leakage. Lastly, improper installation of the camlock could cause it not to function correctly and potentially result in a hazardous situation. It is important for anyone who works with threaded camlocks to be aware of these potential issues so they can take steps to prevent them from occurring.

Threaded camlocks are an essential component of many industrial systems and can provide a secure connection between two pipes or hoses. With the right knowledge, installation is relatively straightforward and maintenance is simple with regular checks for thread wear as well as lubrication of seals and gaskets. It’s important to be aware of potential problems such as worn threads, damaged seals or improper installation so that they can be avoided in order to ensure safe operation. With these tips in mind, you’ll have no trouble using threaded camlocks in your own system!